- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Life Science

- Steel and Metallurgical Industry

- Efficient metalworking using sensor and automation technology

- Drive Technology

- Mobile Equipment

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- Automobile industry and suppliers

- Plastic Industry

- Energy Production

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Intralogistics automation: improve efficiency and throughput

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

Components for hydraulics and pneumatics

Maximizing efficiency and reliability with advanced sensor and networking technologies

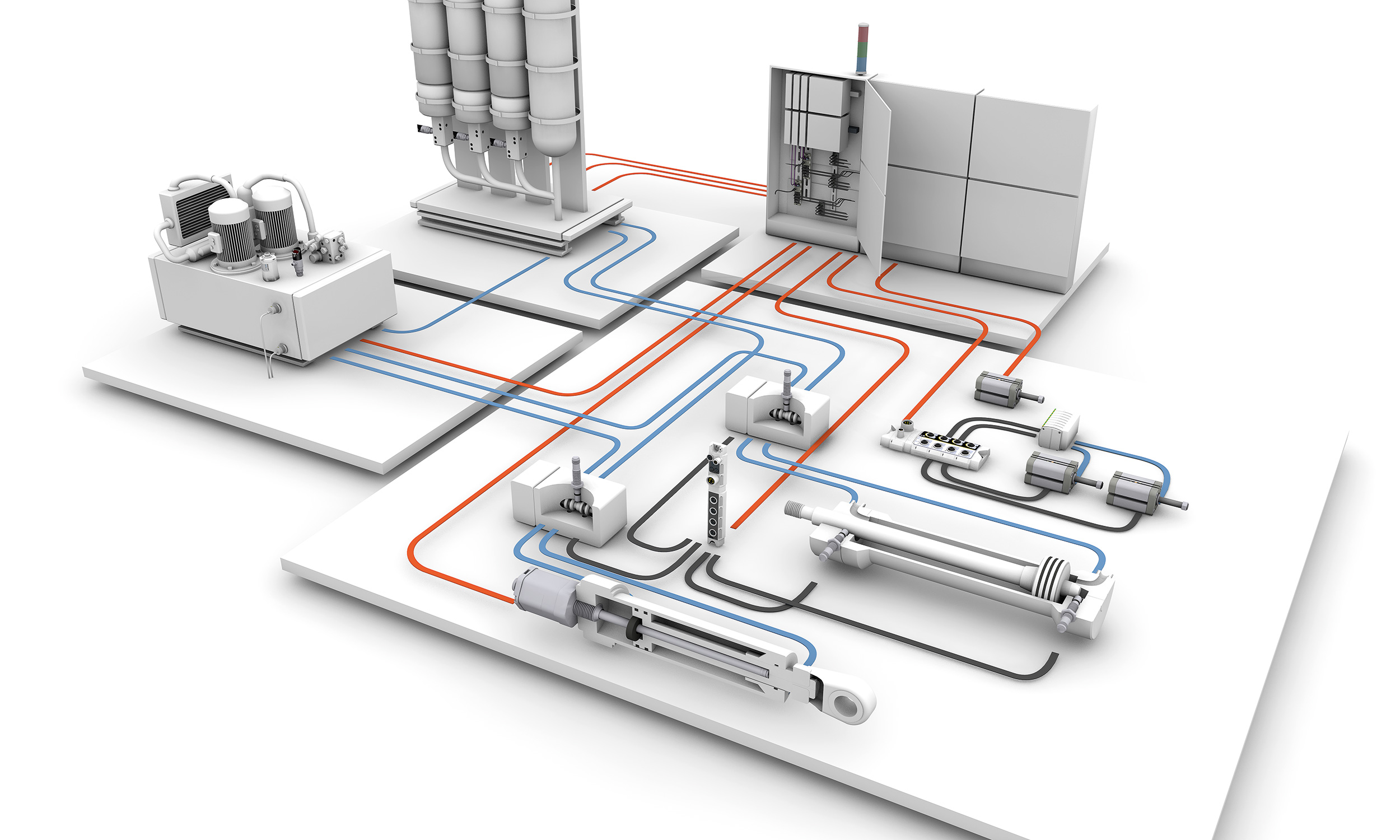

At Balluff, we provide cutting-edge components for hydraulics and pneumatics that enable the seamless integration of advanced sensor and monitoring technologies into your fluid power systems. Our solutions are designed to improve efficiency, ensure precision, and minimize downtime across a wide range of applications.

Discover innovative solutions for hydraulic and pneumatic systems tailored to your needs.

We offer various technologies for monitoring travel and position as well as pressure, temperature, flow and level. This wide range provides users with both process and service data.

Whether you choose conventional solutions or wish to implement IIoT-capable applications, Balluff offers partnering support tailored to your needs from a single source.

Further examples to suit individual areas of use

From the hydraulic system to the digital drive solution

Sensors and actuators with IO-Link have now become a standard in automation technology. However, the standardized IO-Link protocol (IEC 61131-9) also offers significant advantages in fluid power technology when it comes to project planning, commissioning and monitoring components and the system status:

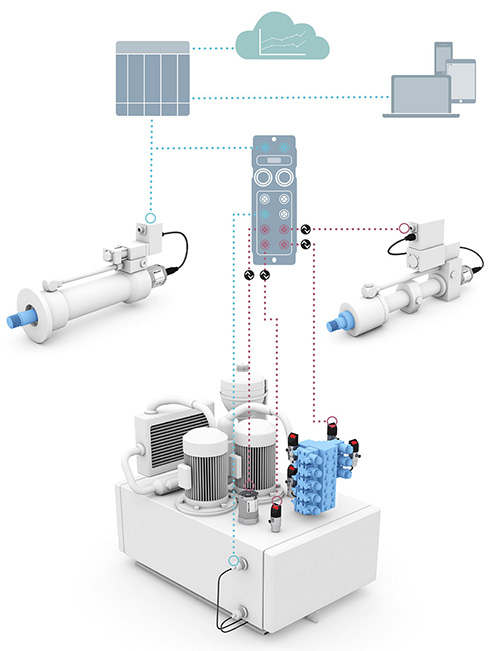

Analysis, data documentation in the cloud

Monitoring, visualization of collected data

Autonomous axis in the field level

Detecting liquid media flow with BFF thermal flow controller

Temperature measurement with BFT temperature sensors

Valve parameterization via IO-Link

Pressure measurement with BSP pressure sensors

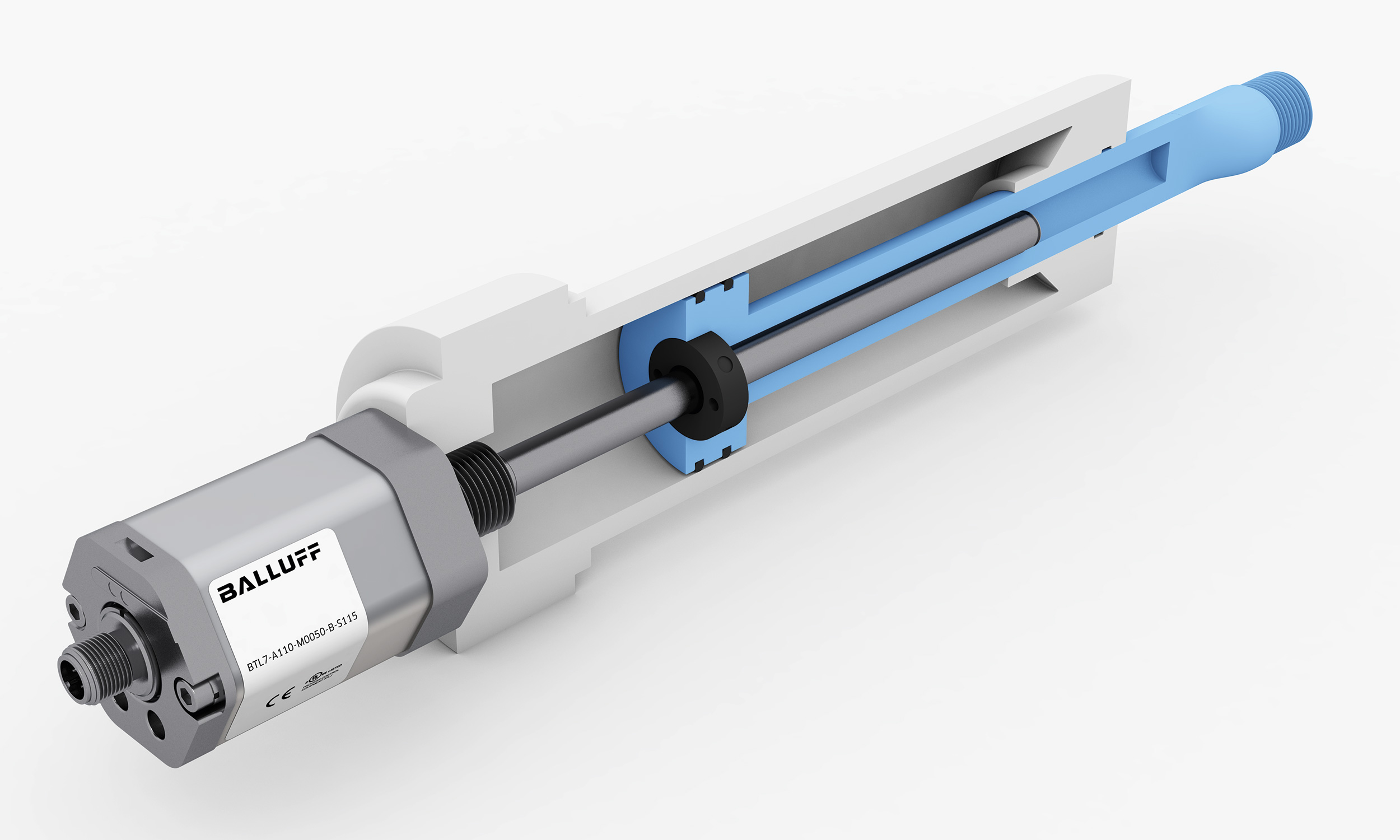

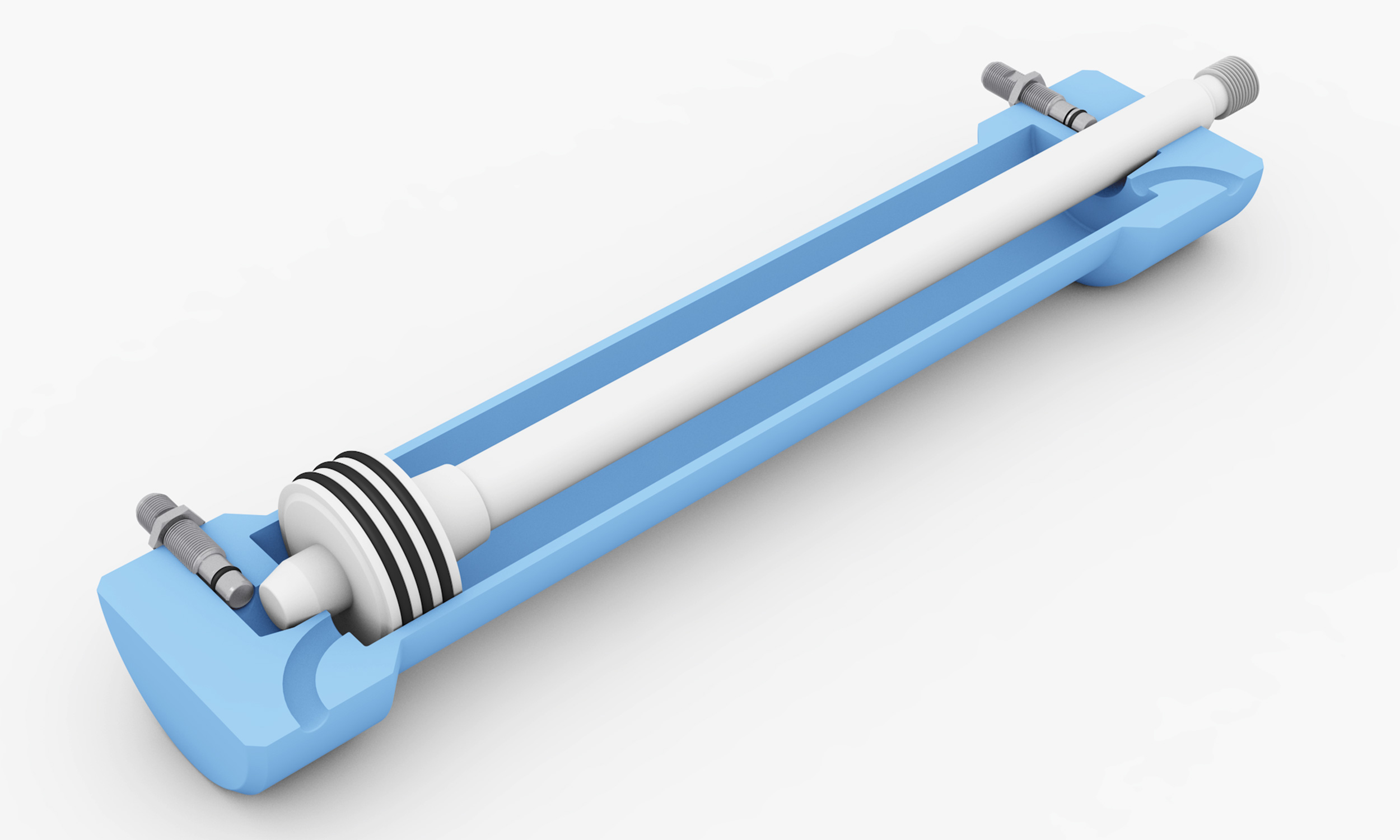

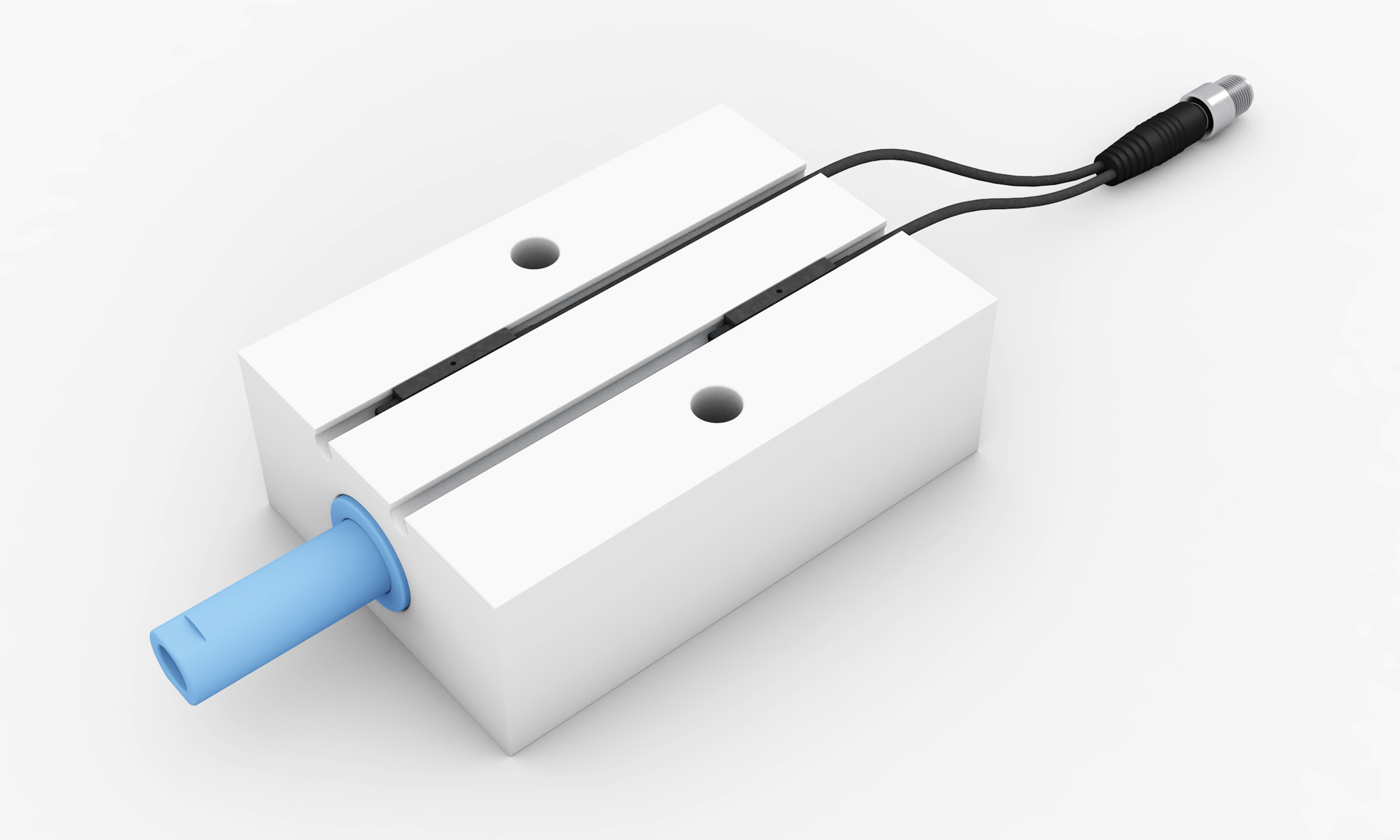

Continuous level detection BTL magnetostrictive linear position sensors

Level monitoring using limit value detection with BCS capacitive sensors

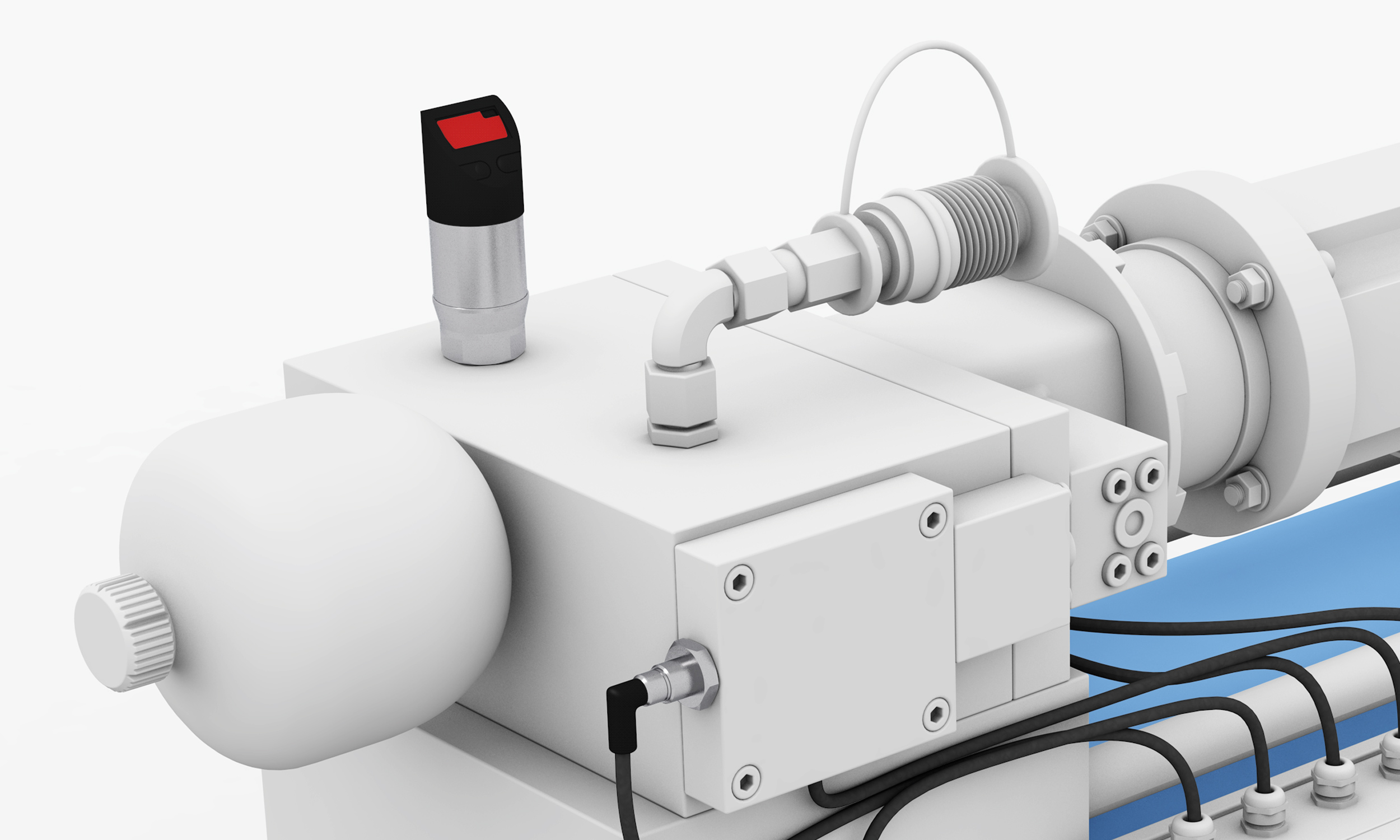

Hydraulic power unit monitoring

A powerful hydraulic pump or compressor and the corresponding e-motor is the heart of many production systems. With the Condition Monitoring Toolkit you get a holistic system to collect and analyze your machine condition data. Our toolkit can evaluate physical variables on your hydraulic unit and keep you reliably informed about significant deviations at an early stage so you can intervene.

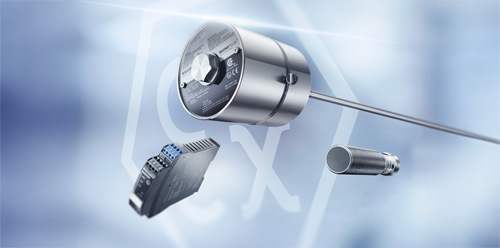

Explosion protection

Fluid power components are also used in areas where there is a risk of explosion. Examples include the monitoring of hydraulic or pneumatic cylinders, the monitoring of hydraulically and pneumatically controlled valves and oil or fill level detection. Balluff offers a range of sensors and transducers with corresponding regional certifications.

Our portfolio

Sensor technology

Networking

Condition Monitoring

Questions? Get in touch!

Videos

-

Position Detection down to the Micron – The Balluff Positioning Sensors

-

Balluff BTL – The New Generation of Magnetostricitve Positioning Systems

-

Fluid Power Technology

-

Industrial Networking with IO-Link – Smart, Easy, Future Proof

-

Balluff Condition Monitoring Solutions

-

Cables, Connectors and Mounting systems – All What You Need

Downloads

-

Industry brochure fluid power technology

-

Sensors and Linear Position Sensors for use in a potentially explosive environment