- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Life Science

- Steel and Metallurgical Industry

- Efficient metalworking using sensor and automation technology

- Drive Technology

- Mobile Equipment

- Advancing battery manufacturing automation: Achieving superior efficiency and quality

- Automobile industry and suppliers

- Plastic Industry

- Energy Production

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

- Intralogistics automation: improve efficiency and throughput

- Robotic sensing: Precision and efficiency in robotics automation

- Automation in the semiconductor industry

- Components for hydraulics and pneumatics

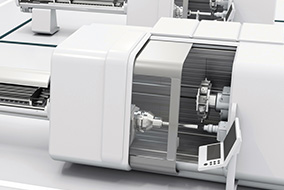

Efficient metalworking using sensor and automation technology

Solutions with robust sensor technology, IO-Link, condition monitoring and digital twins for precise machining and optimally controlled machine tools

Consistent precision manufacturing is crucial for quality and productivity, whether in drive technology, tool and mold making, mobility or medical technology. To meet these requirements, Balluff offers a comprehensive portfolio of robust sensors, identification solutions (RFID, Tool-ID) and network technologies that have been specially developed for workshops, machining operations and modern machine tools. These products are robust for use in harsh manufacturing environments so that plant operators can choose the right sensor technology for their application.

With condition monitoring solutions, you can keep an eye on the condition of your machines at all times and initiate preventive maintenance measures to increase overall equipment effectiveness (OEE). Thanks to IO-Link technology, sensor data is transmitted digitally and interference-free. This increases flexibility and reduces the installation effort for IIoT projects. We also offer digital twins that allow you to virtually simulate machines and systems. This allows you to optimize production processes before they are commissioned.

Whether you are an operator of CNC systems, a manufacturing company or a manufacturer of spindles, rotary tables, tool turrets and hydraulic systems, we offer you well-matched sensor and automation technologies to make your production competitive and efficient.

Focus topic: Tool management, process monitoring & more strategies for optimized production

Automated RFID-based tool management ensures maximum transparency

Efficient tool management is crucial to the cost-effectiveness of your production. RFID technology can automate the record-keeping and management of your tools, optimize their use and minimize downtimes. Tool ID solutions from Balluff ensure that every tool is identified, monitored and accurately assigned at all times. This reduces production errors due to incorrect tool selection and demonstrably reduces rejects.

Want to simplify assemblies and machine tools? Reduce complexity and assembly costs with modular automation solutions with integrated sensors. Fewer interfaces and standardized connections simplify maintenance and operation.

Need digital tool management that performs reliably, regardless of frequency range and environment? Frequency-independent RFID systems enable flexible and reliable tool management under all environmental conditions so that tool data is recorded without interference at all times.

The machine tool industry is the backbone of industrial value creation. As a long-standing supplier, we know this: Solutions that make the difference can only be created through partnership-based cooperation. That is what drives us.

Uwe Brandt, Head of Global Market Segment Sales, Metalworking

More efficient with IO-Link: Intelligent networking for your machine tools

Modern machine tools and machining processes require precise and reliable communication between sensors, actuators and control systems. This is exactly what IO-Link enables — end-to-end digital networking at all levels of production. This increases efficiency, reduces downtime and enables you to adapt to changing production requirements.

Transparency in real time

Detailed digital sensor data ensures more precise control of machine tools, clamping systems and handling processes.

Fast adjustments

Central parameterization enables simple format changes and optimizes digital tool management, while sensor and cable changes using standard connectors are easy.

Simple integration

Use standardized interfaces for cost-efficient and scalable automation in every machine and system.

Comprehensive connectivity

Balluff IO-Link masters support all common industrial protocols, including Profinet, EtherNet/IP and EtherCAT. Multi-protocol capability enables seamless integration into various control systems.

Product highlights: Innovative technologies for metalworking

How do you achieve maximum efficiency, precise processes and seamless networking from the sensor to the control level? With Balluff's sensor, network and identification solutions. You can optimize your manufacturing processes and increase your productivity, whether for turning, milling or the fully automatic management of your tools. Our products offer you reliable performance even under the toughest conditions.

Further topics relating to metalworking

Deepen your knowledge with practical solutions and products for special applications in metalworking.

What questions do you have?

Get in touch with our metalworking experts! Feel free to contact us directly. We look forward to hearing from you.Downloads

-

Industry brochure metalworking