Rotary encoder

For controlling, measuring and monitoring rotary movements

The rotary encoders from Balluff are used wherever there are mechanically record values for angles of rotation mechanically. The recorded movements are converted into electrical signals and help you to position all critical machine parts with high precision. The robust processing of the rotary encoders enables use even under extreme conditions such as in food processing and packaging, mobile machinery and mechanical engineering. We have the right encoder for your applications, whether as an absolute or incremental encoder.

Our extensive portfolio of encoders

Incremental encoders

Absolute encoders

The requirements for rotary encoders vary considerably depending on the application. It is therefore important to know the three key differences: Incremental vs. absolute encoders, Singleturn vs. multiturn encoders and optical vs. magnetic measuring principles. They help you to select the right technology for your machines and systems - for maximum accuracy, reliability and efficiency.

Incremental encoders

Speed monitoring and position determination of machines and systems

Incremental encoders record your machine data in comparison to the last data collection. For this purpose, reference values are defined each time the machines - and therefore also the sensors - are switched on. Incremental encoders emit a precisely defined number of pulses per revolution. The signal serves as a measure of the angle or distance traveled. The more pulses generated per revolution, the higher the resolution of the incremental encoder and the more precise the measurement and control of your production systems. The interfaces of incremental encoders include ABZ, sin/cos, TTL (transistor-transistor logic) and HTL (high threshold logic).

Absolute encoders

High-precision positioning and reliable data acquisition in industry

Absolute encoders detect positions and, unlike incremental encoders, assign a unique angular position or value to each signal. With our absolute encoders, the actual position value is available at all times, even after a power failure. Absolute encoders do not require a reference value or homing routine every time the machine is switched on. Your position value is not lost when the machine is switched off and back on. The interfaces of the absolute encoders include RS485, SSI and CAN open.

Singleturn encoders

With singleturn encoders the coded output signals are repeated with each new revolution of the shaft. Singleturn encoders have a measuring range of 360 degrees i.e. exactly one revolution. If the shaft is rotated more than 360 degrees, the output parameters of the further revolutions correspond to the signal of the first revolution. Without additional data processing or corresponding evaluation or monitoring of the output signal, it is therefore not possible to count the total number of complete revolutions that have already taken place on the basis of individual data points with a single-turn encoder.

Multiturn encoders

Multiturn encoderson the other hand, enable the measurement of a measuring range that corresponds to more than 360 degrees. The sensors can therefore generate a unique output signal for each shaft position, for over 8 trillion revolutions. The output signal of the encoders is determined by the number of revolutions and the shaft position within one revolution and is unique within the signal variance of the maximum 8.8 trillion revolutions. This enables a valid and always reliable statement to be made about the encoder revolutions that have already been completed.

Optical encoder: Highest resolution and precision thanks to our optical measuring principle

Optical rotary encoders are sensors that use an optical measuring principle to measure very precisely. Precise and with highest image resolution and generate digital pulses. An optical encoder consists of a transparent code disk that is illuminated by an LED and converts the received data into electrical signals. The optical measuring principle enables maximum precision in data acquisition. This makes optical encoders ideal for use in automation technology.

Magnetic encoders: The robust solution for harsh working environments

Magnetic encoders from Balluff are particularly suitable for use in harsh environmental conditions such as extreme temperatures. They are insensitive to shock and vibration loads and are and are an all-round robust solution among rotary encoders for applications in heavy industry or machine tools. There are no limits to the areas of application, as the compact design enables use even in the smallest machine parts.

Application examples

Application examples from various industrial sectors demonstrate the wide range of uses for rotary encoders. They are used for the precise detection of rotation angle, speed and position in motors, drives, machine tools or conveyor systems. Thanks to their high resolution and robustness, they guarantee reliable, low-wear measurement - even under harsh environmental conditions. They therefore meet a wide range of industrial automation requirements with high precision, dynamics and repeat accuracy.

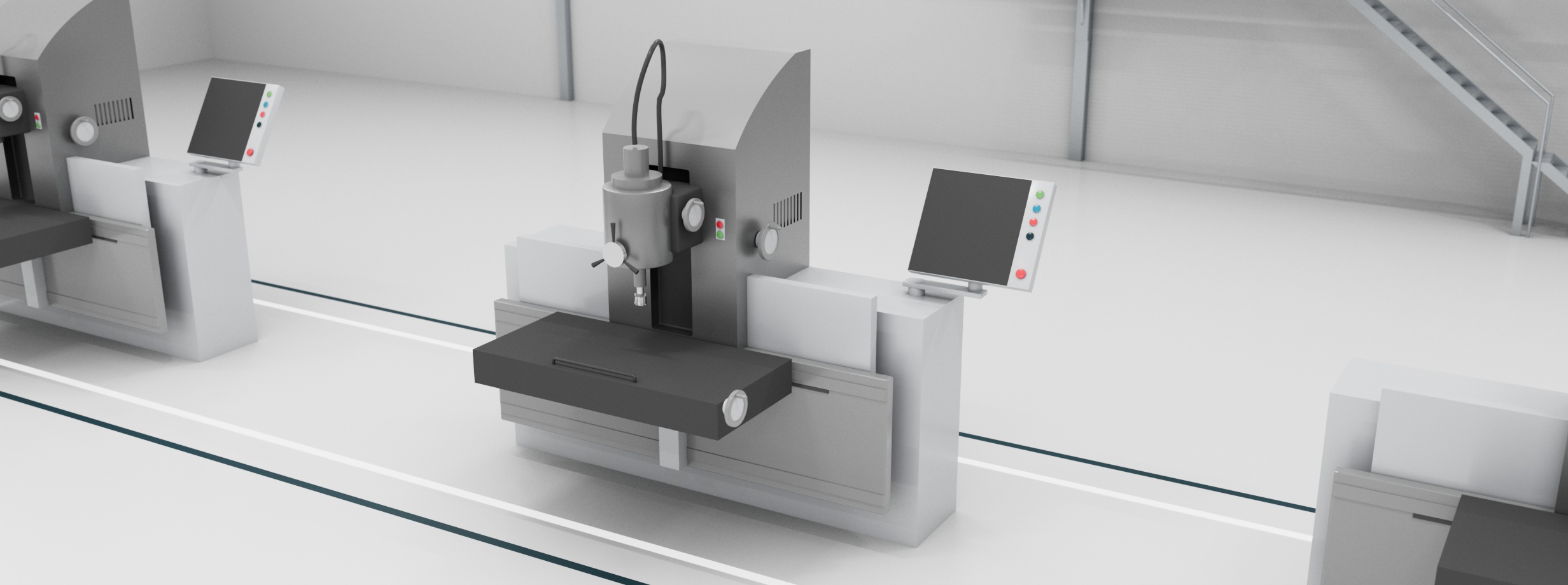

Metalworking: rotary encoders for industrial applications with high accuracy

Rotary encoders from Balluff are used wherever lengths, positions, rotational speeds or rotational movements and angles or angular velocities need to be measured. They convert mechanical movements into digital electrical signals.

Depending on the application, Balluff offers different measuring principles. If high resolution is required, optical encoders are often used. Magnetic encoders are used for applications in harsh environmental conditions. Encoders are also available in a corrosion-resistant version in a stainless steel housing and with protection class IP69K.

Innovation in focus

Expanded encoder portfolio

IO-Link interface for easy integration and increased efficiency

Expertise and advice - how to contact us

Our team of experts is here to help and advise you. If you are unsure which sensor best suits your requirements, we will be happy to help you.Licensing declaration

The following open source components are used: eCos V3.0

Source:http://ecos.sourceware.org/

License:eCOS license