- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

- Condition Monitoring

- Architects of Smart Manufacturing

- Explosion Protection

- Level Detection

- Quality Assurance

- Tough Performers

- Miniaturization

- MicroSPOT

- Comprehensive components and solutions for automated welding

- Ultrasonic sensors – chemically resistant, non-contacting and precise even under pressure

- Capacitive sensor head detects over a large range

- BTL level sensor for maintaining the highest hygienic standards

- Using hydrostatic pressure sensors for detecting the level in storage tanks

- Using magnetostrictive linear position sensors to monitor levels on non-magnetic containers

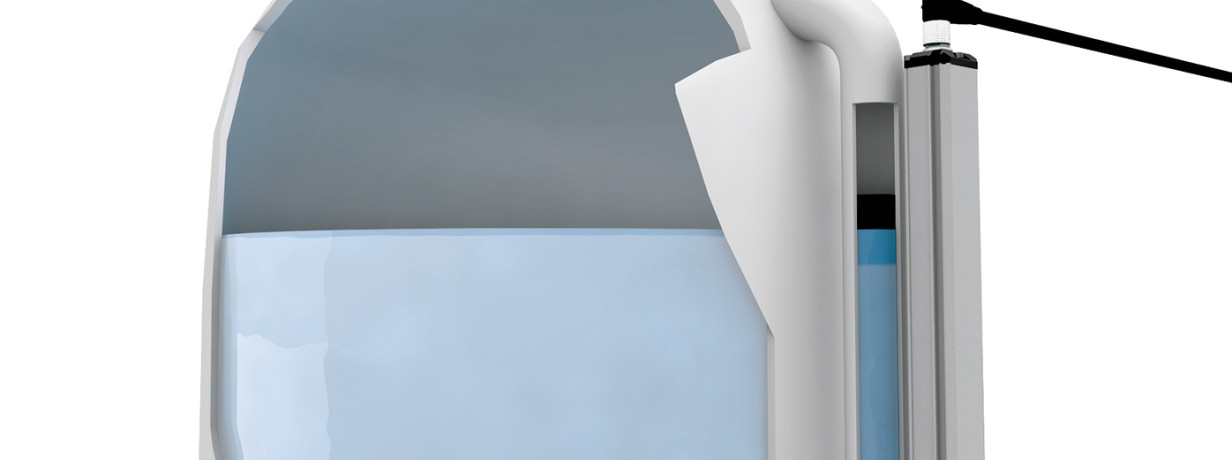

Using magnetostrictive linear position sensors to monitor levels on non-magnetic containers

Our BTL magnetostrictive linear position sensors in the rod-style can be used for non-contacting level monitoring on containers made of non-magnetic materials such as glass, stainless steel or plastic. The container wall can be up to 8 mm thick. A float with integrated magnetic ring is used to indicate the level. The measurement system detects the position of the float from outside the container and sends a signal for processing. Levels of from a few millimeters to as much as 6 meters can be reliably detected.

Features

- Contact-free monitoring

- Can be retrofitted

- Suitable for explosive atmospheres: Designs with ATEX certification available

- Variety of interfaces

- Simple to install on bypass tubes for continuous level measurement