- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

- Condition Monitoring

- Architects of Smart Manufacturing

- Explosion Protection

- Level Detection

- Quality Assurance

- Tough Performers

- Miniaturization

- MicroSPOT

- Comprehensive components and solutions for automated welding

- Ultrasonic sensors – chemically resistant, non-contacting and precise even under pressure

- Capacitive sensor head detects over a large range

- BTL level sensor for maintaining the highest hygienic standards

- Using hydrostatic pressure sensors for detecting the level in storage tanks

- Using magnetostrictive linear position sensors to monitor levels on non-magnetic containers

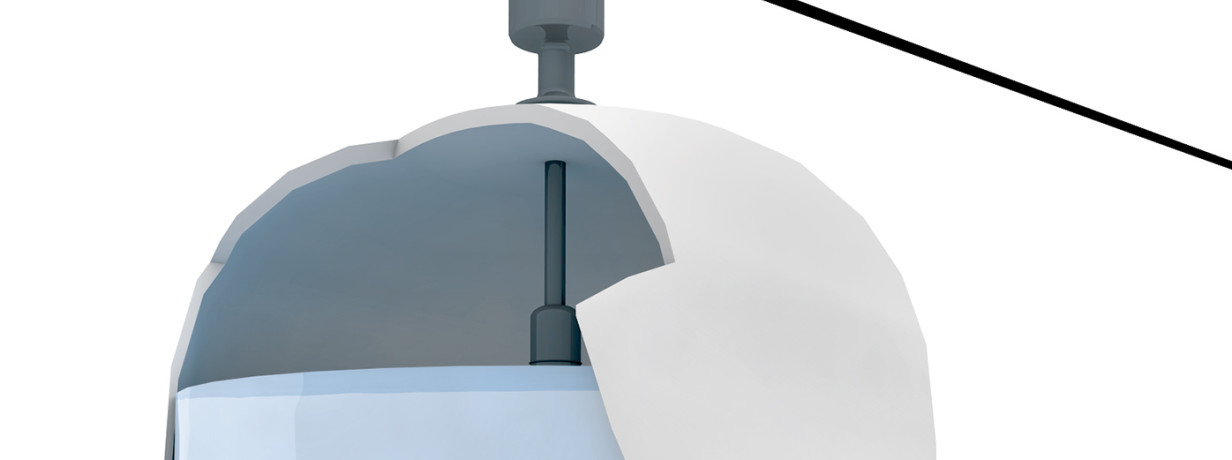

BTL level sensor for maintaining the highest hygienic standards

The strict regulations in the foods industry are no problem for our BTL-SF level sensor. It has proven itself in applications where extreme hygiene is essential, and it meets the highest international hygiene standards. This means it can be used in your equipment anywhere in the world. The level sensor measures down to the micrometer range and enables high filling accuracy.

Features

- Internationally certified quality (Ecolab, 3-A Sanitary Standard, FDA)

- Assured hygiene standards and a long service life thanks to 100% stainless steel

- Can be installed adjustment-free

- Flexible installation using standardized interfaces

- Neutral for all liquids, resilient to foam

- CIP (Clean-in-Place): Easy to clean even while installed

- SIP (Sterilization-in-Place): Suitable for process temperatures up to 130 °C

- Rising and falling signal available