- Matrix Vision solutions now all under the Balluff brand

- IO-Link: Intelligent solutions for modern automation

- Smart Automation and Monitoring System

- Condition Monitoring

- Architects of Smart Manufacturing

- Explosion Protection

- Level Detection

- Quality Assurance

- Tough Performers

- Miniaturization

- MicroSPOT

- Comprehensive components and solutions for automated welding

- Simplifying Network Topology

- Transmit power and data without contact

- Full transparency all the time

- For high production quality

- More flexibility was never easier

- Continual, non-contact linear position measurement

- Complete ID solutions for transfer systems

- Fast parameter replacement, minimum scrap

- Simple handling, versatile application and economical

- Simplify industrial vision applications

- Automated tool management with RFID

- Information exchange and data transport across all levels

- Easy Hazardous Area Safeguarding

- Wear-free and tamper-proof

- For pneumatics and hydraulics

- For extreme welding conditions

- Condition monitoring and condition-based maintenance

Simplifying Network Topology

Interconnected, noise-free communication

All devices become IO-Link capable

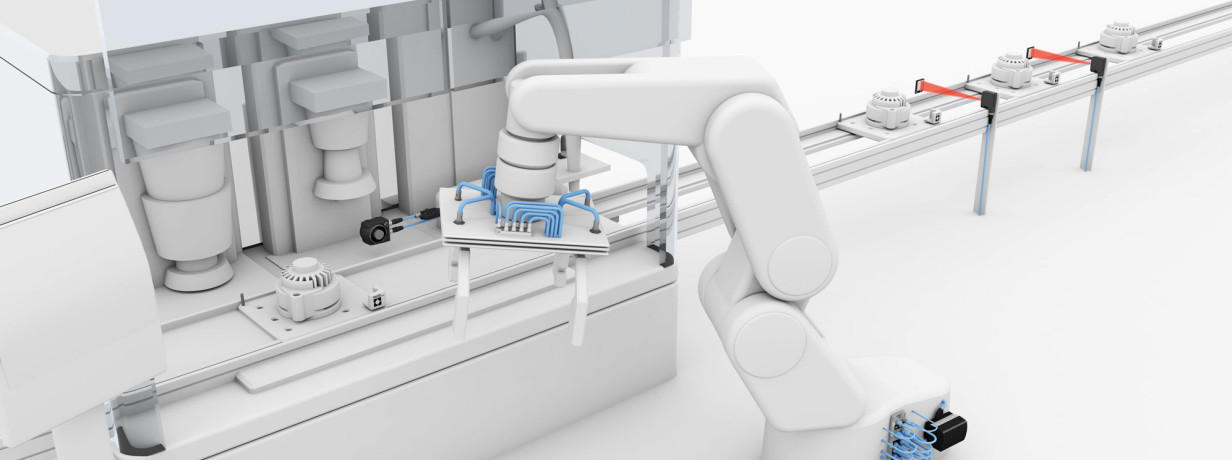

Modern robotics equipment requires many sensors – especially in the robot arm which, for proper dynamics and minimum energy consumption, need to have as little mass as possible. Cumbersome wiring of multiple conductor cables can make this difficult.

These problems are minimized with IO-Link. IO-Link requires only a traditional industrial cable which is simple to install. IO-Link also ensures noise immunity with intelligent devices without the need for shielded cables.

Whether Profibus/Profinet over CC-Link/CC-Link IE-Field, Devicenet or Ethernet/IP and EtherCAT, our IO-Link masters let you use IO-Link with any controller. After all, IO-Link is fieldbus-neutral. With IO-Link you can bring a wide variety of devices together in the structure so that even the most complex tasks, including robotics and beyond, can be simply mastered with the greatest possible flexibility. The universal IO-Link interface integrates intelligent devices into the controller. Likewise you can integrate standard analog sensors into the controller using our IO-Link analog converters. Or simply connect them to our IO-Link hubs, which can digitize the analog input signals and pass them on to the IO-Link master. With the IO-Link master you can also control actuators and valve terminals. Simply use the valve interface to connect the valve terminal to the IO-Link master. Again, all you need is a standard cable to make use of the full functionality.

A Balluff IO-Link sensor hub bundles the signals from up to 16 sensors or actuators. Another highlight is our cascadable hubs with expansion port which allow you to connect an additional sensor hub or a valve terminal. If these hubs are cascaded with an additional hub and connected to our 16x IO-Link master, a module transmits up to 496 inputs/outputs.

Downloads

-

Technical catalog – products for efficient automation

-

Performance portfolio – We speak IO-Link. Worldwide – in all areas