Fieldbus technology: Connection via fieldbus modules

How data transfer via fieldbus modules works

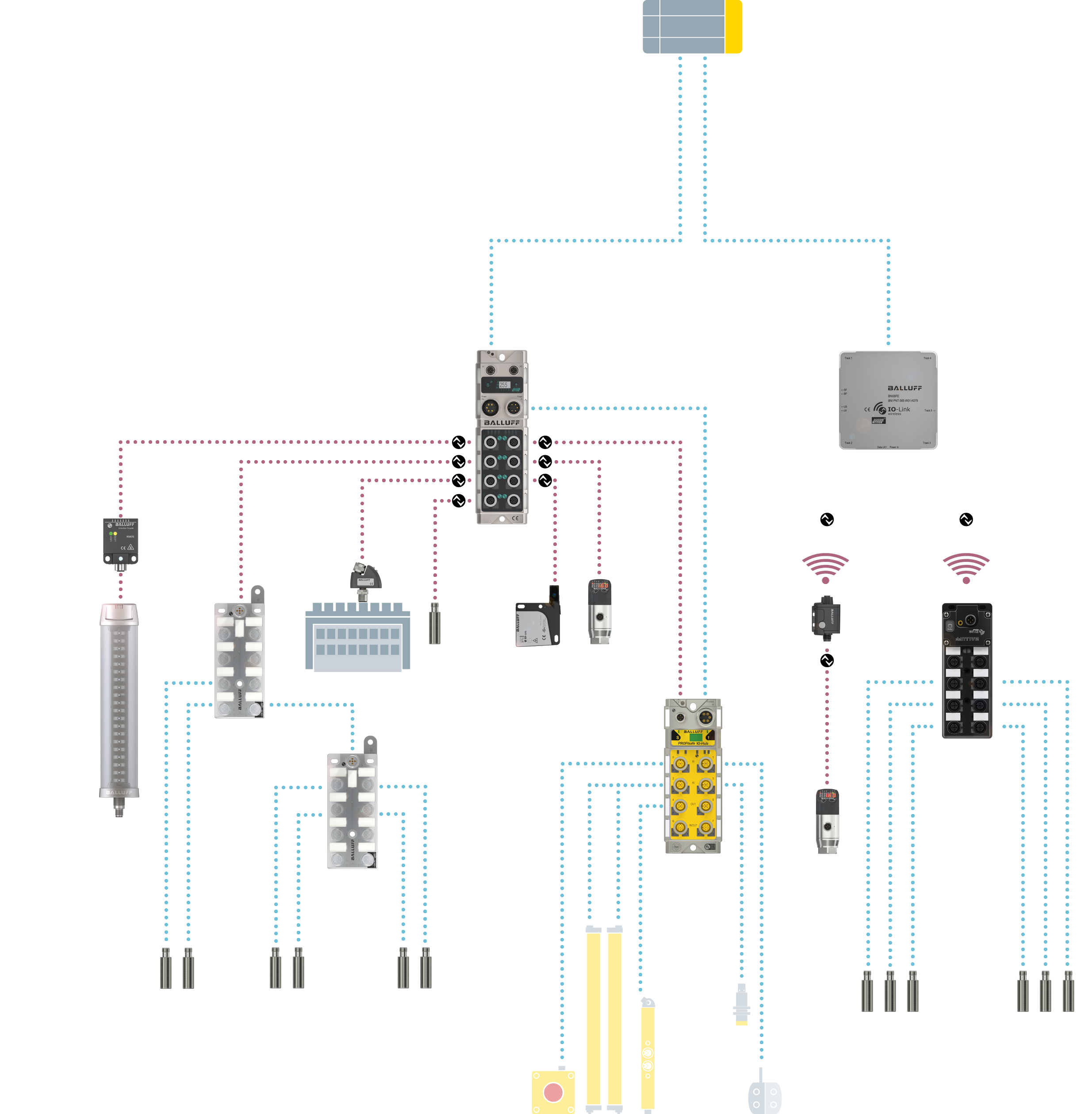

Data transfer via fieldbus modules is a central component of modern automation technology and industrial communication. Fieldbuses enable the networking of controllers, sensors and actuators in an industrial environment, ensuring efficient and reliable data transfer between the various components.

What is a fieldbus?

A fieldbus is a digital communication network that is used in automation technology to network various devices such as sensors, actuators and controllers. In contrast to conventional cabling, which is often based on point-to-point connections, a fieldbus enables communication via a shared network. This is achieved by using standardized protocols that regulate the exchange of data between the devices. Fieldbuses are able to transfer data in real time and support various topologies, such as line, tree or ring structures.

What are the advantages of a fieldbus?

The use of fieldbuses in automation technology offers numerous advantages that significantly increase the efficiency and flexibility of production systems. The advantage of these fieldbuses lies not only in the communication over long distances, but also in the diagnostic function. The reduction in cabling costs and the ability to network several devices via a common communication medium make installation simpler and more cost-effective.Fieldbuses also enable real-time communication, which is essential for time-critical applications.

What are the differences between fieldbuses?

Fieldbuses differ in several aspects. These differences influence the selection of the appropriate fieldbus for a particular application, based on the specific requirements of the industrial environment. Some of them are:

Topology: Fieldbuses can support different network structures, such as line, star, ring or tree topologies. The choice of topology influences the flexibility and scalability of the system.

Data transmission rate: Different fieldbus systems offer different data transmission rates. The required data rate depends on the application and the required response times.

Field of application: Some fieldbuses are specially developed for specific industries or applications. Fieldbus modules thus differ in their housing material, which is selected depending on their operating environment. If they are used in welding systems, for example, a module in a glass fiber reinforced plastic housing is suitable. Stainless steel is recommended for use in hygienic environments.

Safety functions: Some fieldbuses offer integrated safety functions that are required for applications in safety-critical environments.

Protocol standards: Each fieldbus has its own communication protocol that defines the way data is transmitted. Some are proprietary, while others are internationally standardized, which facilitates interoperability between devices from different manufacturers. Examples include Profibus, CAN bus, Modbus and Ethernet/IP.

What is a fieldbus module?

Fieldbus modules play a crucial role in the integration and functionality of fieldbus systems in industrial automation. A fieldbus module acts as an interface between field devices (such as sensors and actuators) and the fieldbus network. It enables the transmission of data and commands and ensures that the various components can communicate efficiently with each other. Communication takes place via a specific protocol that enables the exchange of data and control commands between the devices and the controller. The module translates the signals between the network and the connected devices.

Here you will find an overview of common fieldbus systems

Fieldbus technologies - for powerful performance

Fieldbus systems and IO-Link

The combination of fieldbus systems with IO-Link enables seamless integration of sensors and actuators into existing automation architectures. IO-Link acts as an extension of the fieldbus systems and makes it possible to connect a large number of devices via a standardized interface. This reduces the amount of cabling required and simplifies installation.

By using IO-Link in conjunction with fieldbus systems, companies can benefit from improved data communication, as it enables the transmission of process data, as well as diagnostic data and parameterization information. This leads to better monitoring and maintenance of devices, which reduces downtime and increases efficiency.

In addition, you can easily adapt and expand automation solutions using IO-Link by adding new IO-Link-enabled devices without having to change the entire infrastructure. This is particularly beneficial in dynamic production environments where requirements can change quickly.

Integrating IO-Link into existing fieldbus systems can also lead to cost savings. By reducing the amount of cabling and simplifying maintenance, installation and operating costs are reduced. In addition, the improved diagnostic technology enables proactive maintenance, which minimizes expensive downtime.