17.06.2020

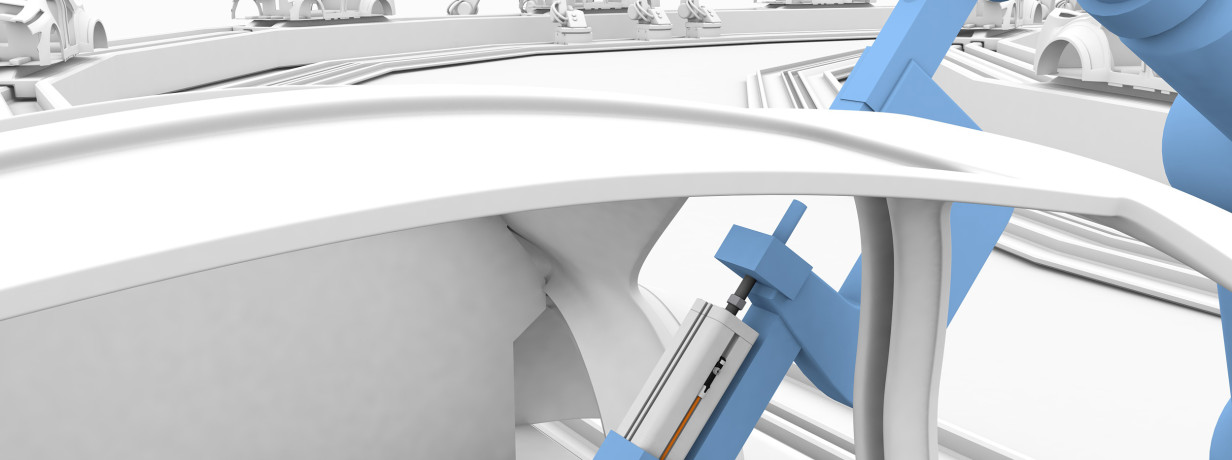

Weld-immune Magnetic Field Sensor for Intelligent Position Feedback

For more process security and greater equipment up-time

Welding is a harsh environment: High temperatures and flying sparks can cause heat damage, and weld spatter can stick to sensors and cables, impairing their functionality. High welding currents generate magnetic interference fields, which can also affect sensor function. This isn't an issue with our interference-immune BMF 415KW magnetic field sensor. It was designed specifically for use in pneumatic drives, which are used in weld field applications. Its weld spark-resistant cable contributes to high equipment up-time.

For greater process security, the sensor can detect magnetic interference fields and suppress them.

An IO-Link interface can be used to read comprehensive diagnostic data and obtain information, for example, about the device status or current ambient conditions.

Features

- Immune to magnetic interference fields from high welding currents (AC and MFDC equipment)

- IO-Link versions: Interference suppression time configurable from 50 to 1000 ms

- Flexibility: M8 or M12 connector, open cable end

- Condition monitoring via IO-Link: e.g. signal quality, device temperature or operating hours

- Weld spark-resistant TPU or silicon cable

Related topics

Downloads

-

Weld-immune magnetic field sensor for intelligent position feedback