16.05.2025

Image capture beyond the visible spectrum

Expanding the possibilities of optical inspection with short wave infrared (SWIR) and ultraviolet (UV) cameras

The basics

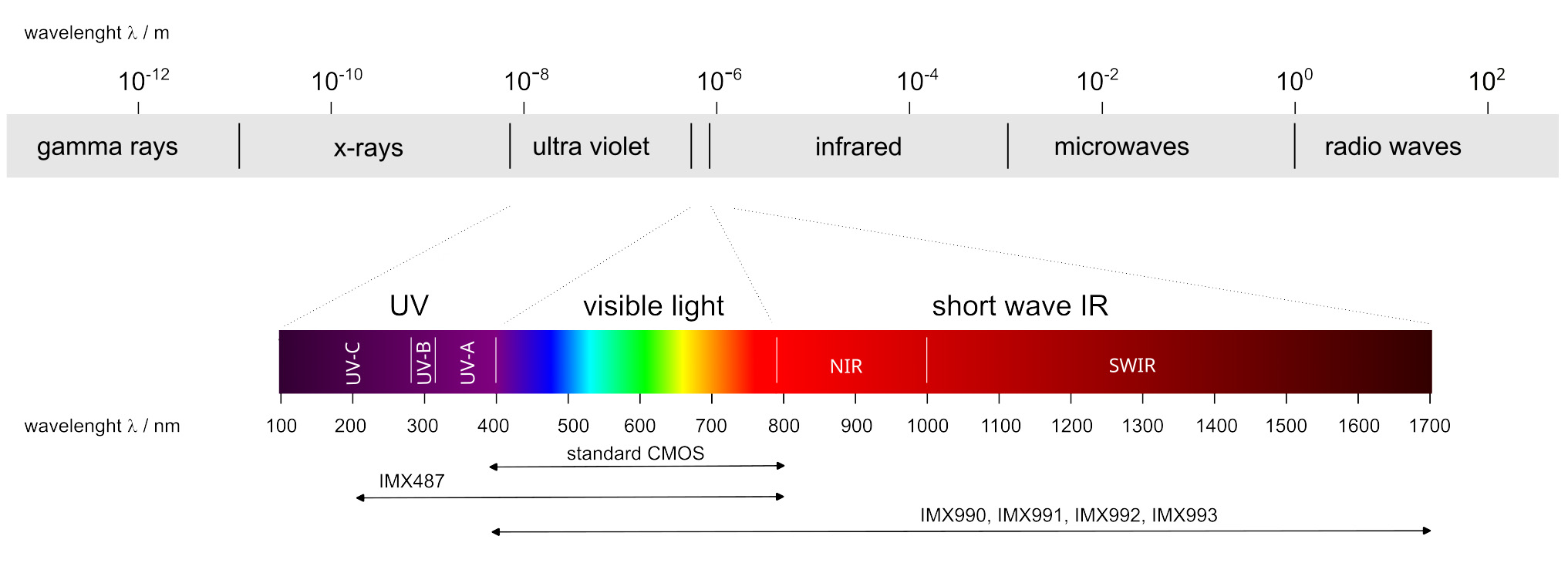

When it comes to industrial image processing applications, one often thinks of detecting features that are also visible to the human eye. Most industrial cameras work in the visible light range (380 nm -780 nm) and have sufficient sensitivity in the near infrared range.

Detecting in wavelengths outside this range can reveal object features and properties that remain hidden to the human eye and conventional cameras.

Wavelengths below the visible range are referred to as ultraviolet light or ultraviolet radiation (UV, 380 nm - 100 nm). Wavelengths above 780 nm are in the infrared range, while the range up to 1000 nm is referred to as near infrared (NIR) and the range up to 1700 nm as short wave infrared (SWIR).

Electromagnetic spectrum and SWIR wavelengths

With suitable image sensors, the detection spectrum can be extended into the UV to SWIR ranges.

With suitable image sensors, the detection spectrum can be extended into the UV to SWIR ranges.

Image capture in the UV range

An example from the semiconductor industry

One of the many applications in the ultraviolet range is the inspection of wafers. The microscopically small semiconductor structures require a significantly higher camera resolution for inspection. When capturing images of materials such as glass and plastic, they appear transparent or translucent when standard cameras are used.

However, their translucency is different in the UV spectrum, meaning that these materials can be identified using UV imaging. Balluff cameras meet these requirements by using the latest sensor technologies that detect the short wavelengths of ultraviolet light to achieve high-resolution detail.

With the release of the Sony IMX487 sensor from the Pregius S series, the visible spectrum is extended to include the UV range down to 200 nm. The sensor's high resolution of 8.1 MPixel also allows very detailed images to be taken in this spectral range.

UV sensor key figures:

|

Imaging sensor |

Sony IMX487 |

|

Sensor type |

2/3" global shutter CMOS |

|

Resolution |

8.1 MP (2856 x 2848 pixels) |

|

Pixel size |

2.74 µm |

|

Frame rate ADC 8-bit |

194 fps |

|

Frame rate ADC 10-bit |

193 fps |

|

Frame rate ADC 12-bit |

127 fps |

SWIR image processing

Image processing in the short wave infrared range (short wave IR or SWIR) is becoming increasingly important in inspection, sorting and quality control. SWIR refers to the short-wave infrared range from 800 nm to 1700 nm, sometimes also the range above the near infrared (NIR) from 1000 nm to 1700 nm. Longer wavelengths are also referred to as thermal radiation, which is emitted by the object itself.

The SWIR spectrum is more similar to visible light in its properties, where objects reflect or absorb photons. Due to the special absorption properties in the SWIR range, it is possible, for example, to inspect foodstuffs, especially agricultural products, as well as fill levels in opaque plastic containers. SWIR sensors also offer advantages in monitoring tasks, as objects of interest can still be easily detected even in smoke or fog. SWIR sensors are also used in semiconductor inspection, since silicon appears transparent in SWIR light.

The sensors in the Sony SWIR series (IMX990, IMX991, IMX992 and IMX993) uniquely combine the detection of both visible light and SWIR wavelengths over a range of 400 nm to 1700 nm. At the same time, a lower pixel pitch and smaller pixel sizes are achieved thanks to a special bonding technique.

This means that high-resolution cameras and more precise inspection systems can be used for this wavelength range.

Overview of SWIR sensors

|

Imaging sensor |

Sony IMX991 |

Sony IMX990 |

Sony IMX993 |

Sony IMX992 |

|

Sensor type |

1/4" global shutter CMOS |

1/2" global shutter CMOS |

1/1.8" global shutter CMOS |

1/1.4" global shutter CMOS |

|

resolution |

0.34 MP (656 x 520 pixels) |

1.34 MP (1296 x 1032 pixels) |

3.2 MP (2080 x 1544 pixels) |

5.3 MP (2592 x 2056 pixels) |

|

Pixel size |

5 µm |

5 µm |

3.45 µm |

3.45 µm |

|

Frame rate ADC 8-bit |

258 fps |

134 fps |

170 fps |

130 fps |

|

Frame rate ADC 10-bit |

240 fps |

125 fps |

150 fps |

120 fps |

|

Frame rate ADC 12-bit |

137 fps |

71 fps |

90 fps |

70 fps |

New functions

HCG (High Conversion Gain) / LCG (Low Conversion Gain) function: A switching function that amplifies the signal immediately after converting light into an electrical signal, reducing subsequent noise and enabling the capture of low-noise images in low light conditions.

DRRS (Dual Read Rolling Shutter) function: Reduces noise to approximately 1/4 of the noise level normally observed without DRRS, enabling the capture of images with reduced noise.

Other camera benefits:

Low power consumption: For example, the BVS CA-GX0 GigE camera with the IMX991 sensor consumes only about 2.9 W of power.

Camera cooling options: Heat sink, cooling tube and thermoelectrically cooled (TEC) variants for demanding environments and applications.

Wondering if Short Wave Infrared (SWIR) inspection suits your needs?

Send materials for free testing in our SWIR Lab today. Our SWIR Application Laboratory will test your materials to see if SWIR imaging is beneficial for your processes.Overview of camera families and interfaces for SWIR and UV cameras

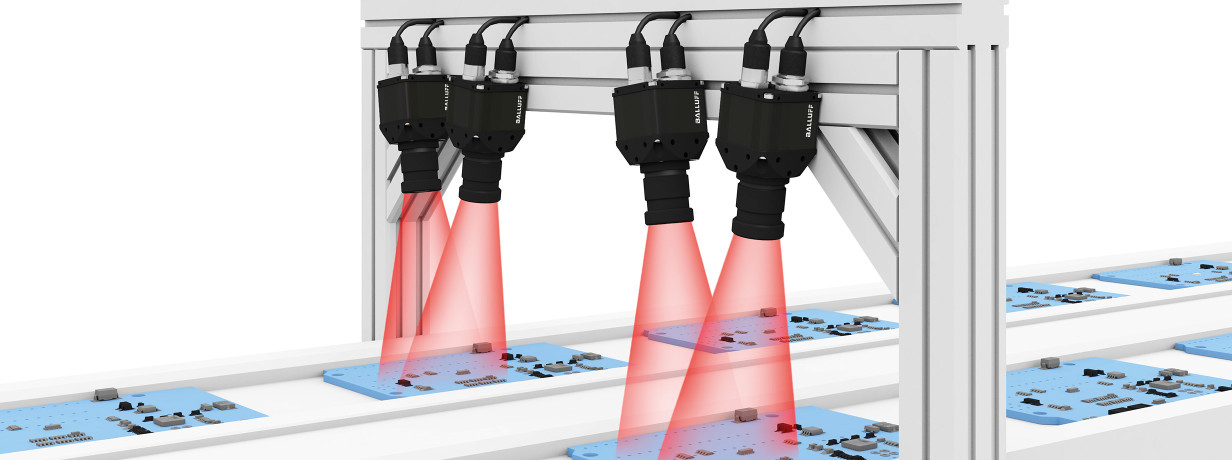

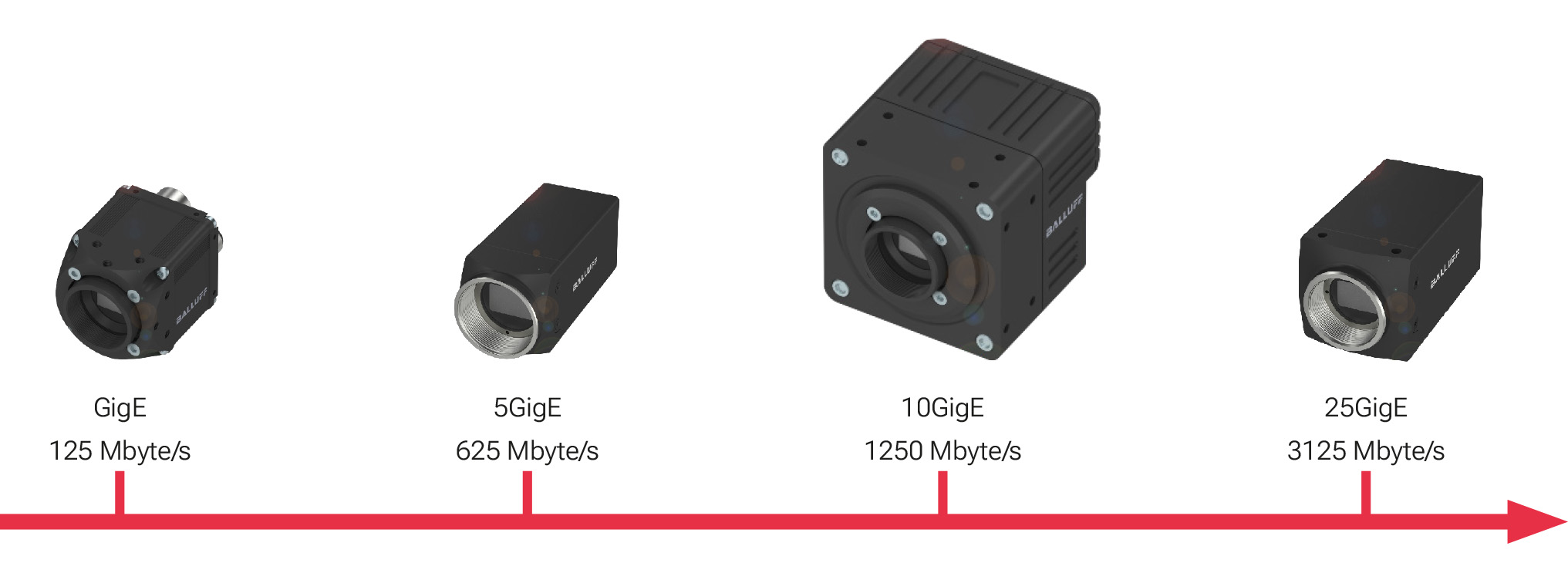

Our existing GigE camera platforms make the use of SWIR and UV technology particularly easy. You benefit from GigE Vision and GenICam compatibility without changing the integration and handling of the cameras from existing industrial cameras.

GigEBVS CA-GX0 series |

5GigEBVS CA-GV series |

10GigEBVS CA-GT series |

25GigEBVS CA-GW Series |

|---|---|---|---|

|

|

|

|

|

|

The scalable machine vision interface Maximum individual configurability of mechanical and electrical properties, largest selection of sensors up to 31.5 MP, various digital inputs and outputs possible, compact housing with many mounting options, available with M12 industrial connectors for GigE and I/O interface, optional IP67 housing. |

Lowest power consumption in a very compact housing Small form factor of 29 × 29 mm, best thermal properties due to the lowest power consumption, power supply and data transmission via one cable using PoE, backwards compatible with 2.5 GigE and 1 GigE interfaces, optionally with larger lens holder for large sensors. |

High-speed transmission rate with excellent image quality Precise synchronization with Precision Time Protocol (PTP) in accordance with IEEE1588, power supply and data transmission via one cable using PoE+, integrated camera cooling, lens holder available in C and M42 mount, 10 GigE connection via standard fibre optic SFP+, Multi-Core Acquisition Optimizer (MAO), 1245 MB/s without image loss. |

Highest performance in all dimensions Use of the RoCE v2 protocol for low-latency, high-throughput data transmission, easy implementation with GigE Vision standard, cost-effective long-distance connection with standard SFP28 fiber optic connection technology, small form factor of 40 x 40 mm, optionally with larger lens holder for large sensors. |

| To the cameras | To the cameras | To the cameras | To the cameras |

USB 3 - BVS CA-SF series

High performance with plug-and-play

High-quality CMOS sensors up to 31.5 MP and up to 12 bits per pixel, internal image pre-processing in real time, flow control for real-time sequences, widespread plug-and-play interface, hardware and software compatibility thanks to USB3 Vision standard and GenICam, also available as a board-level camera.

Application examples

The SWIR spectrum can be used to check agricultural products or fill levels in opaque plastic containers, for example. SWIR sensors also offer advantages for monitoring tasks, as the objects of interest can still be easily detected even in smoke or fog.

In the food industry, for example, SWIR cameras can be used to detect foreign objects in foodstuffs.

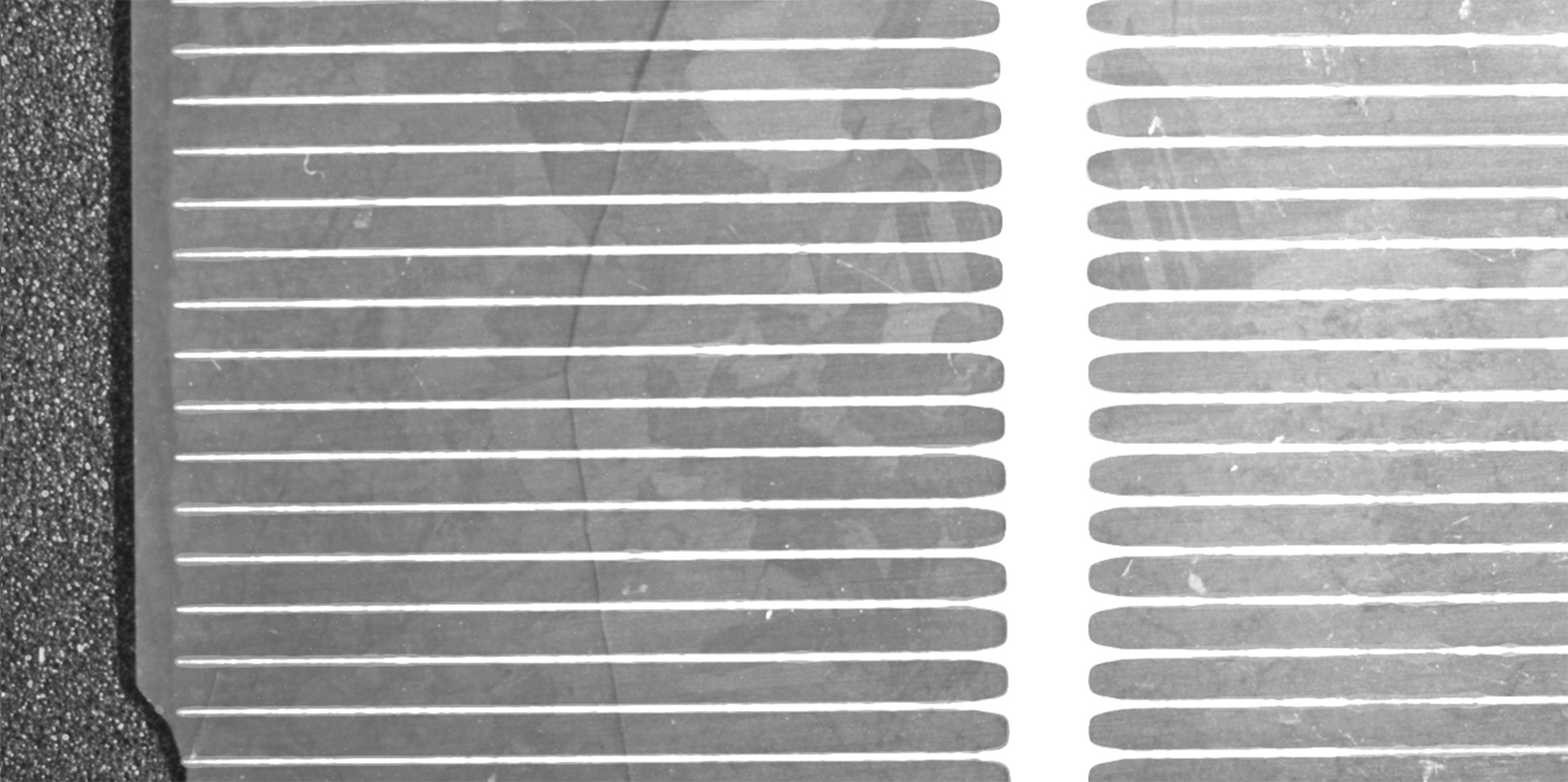

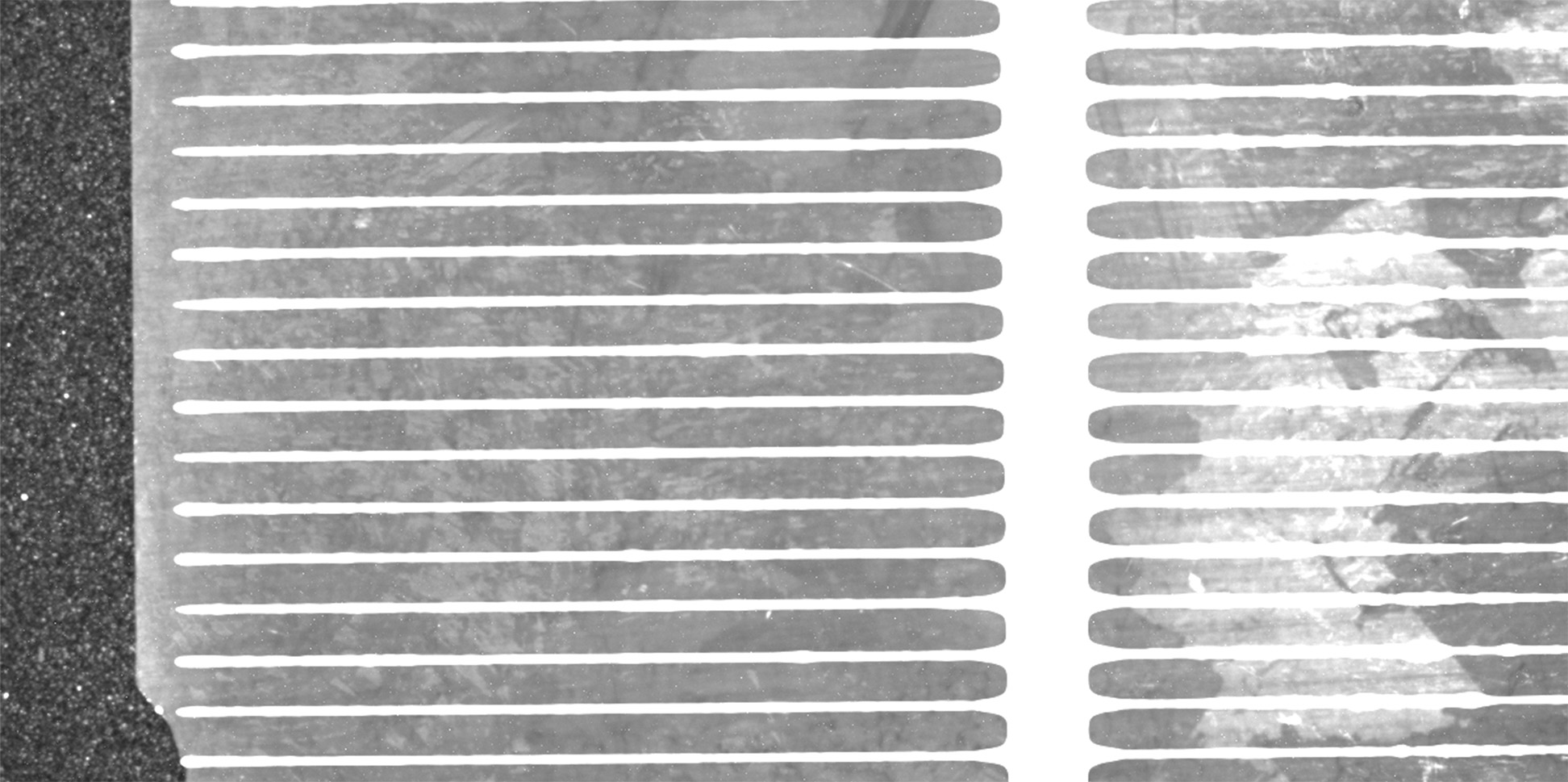

Left: visible spectrum | right: SWIR

As silicon appears transparent in the SWIR spectrum, SWIR cameras are also used in the semiconductor industry to detect damage and production defects.

Left: visible spectrum | right: SWIR

Do you have any questions, requests or suggestions?

Do you have any questions or would you like to find out more? Feel free to contact us directly. We look forward to hearing from you.Downloads

-

Industrial cameras with SWIR and UV sensors