The Condition Monitoring (BCM) Assistant

With just a few clicks, you can set BCM sensors optimally to your application. In addition to various ISO standards for a wide range of machine types, it also gives you access to an extensive database with more than 160,000 types of sensor.

Get the most out of your BCM sensors to ensure the availability of your systems.

Monitoring according to ISO standards

Based on your information, the assistant can apply the appropriate ISO standard to your machine.

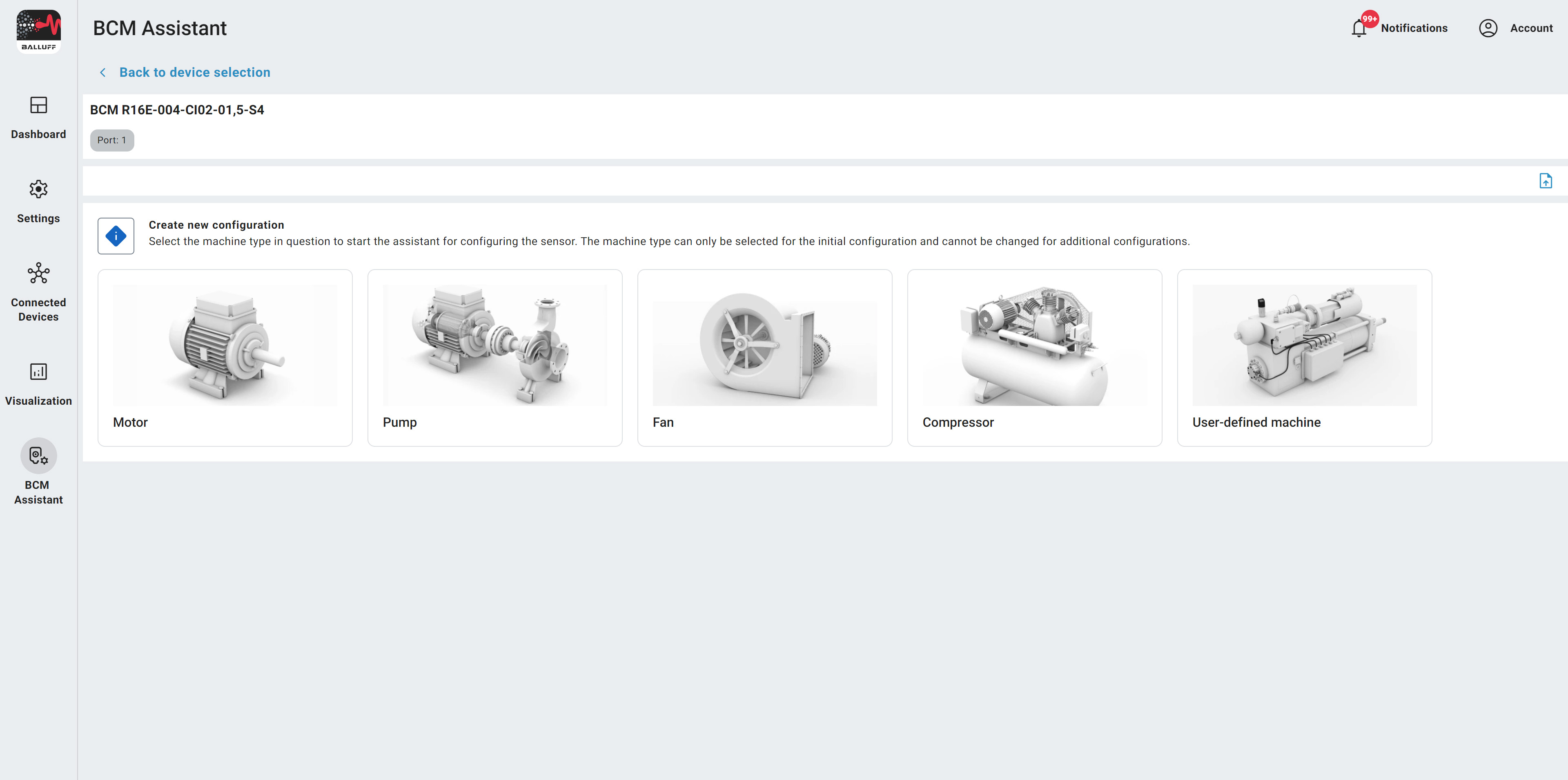

Select which machine type (e.g. pump) is to be monitored.

Select which machine type (e.g. pump) is to be monitored.

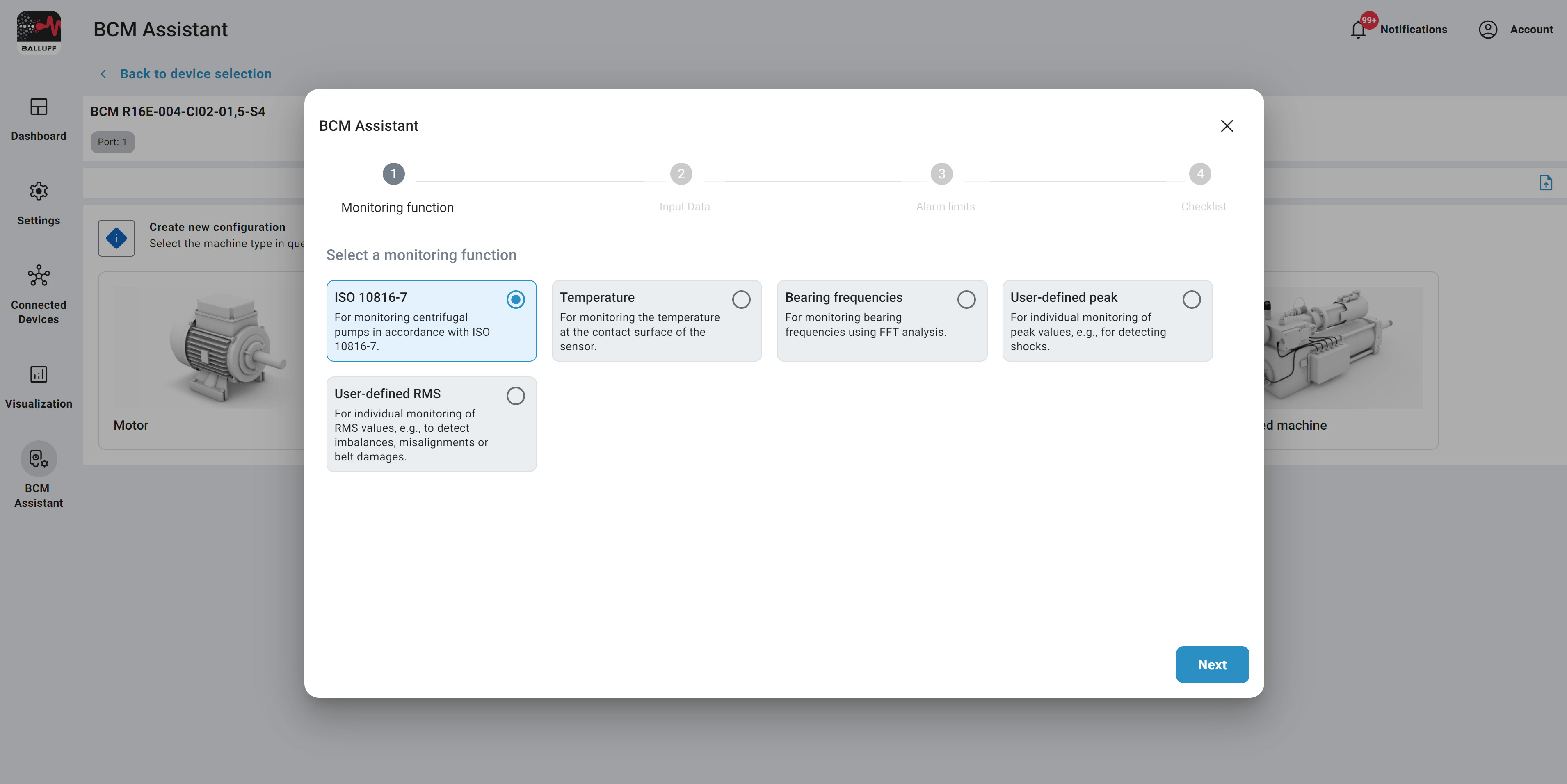

Specify which monitoring function (e.g. ISO 10816-7) the sensor should perform.

Specify which monitoring function (e.g. ISO 10816-7) the sensor should perform.

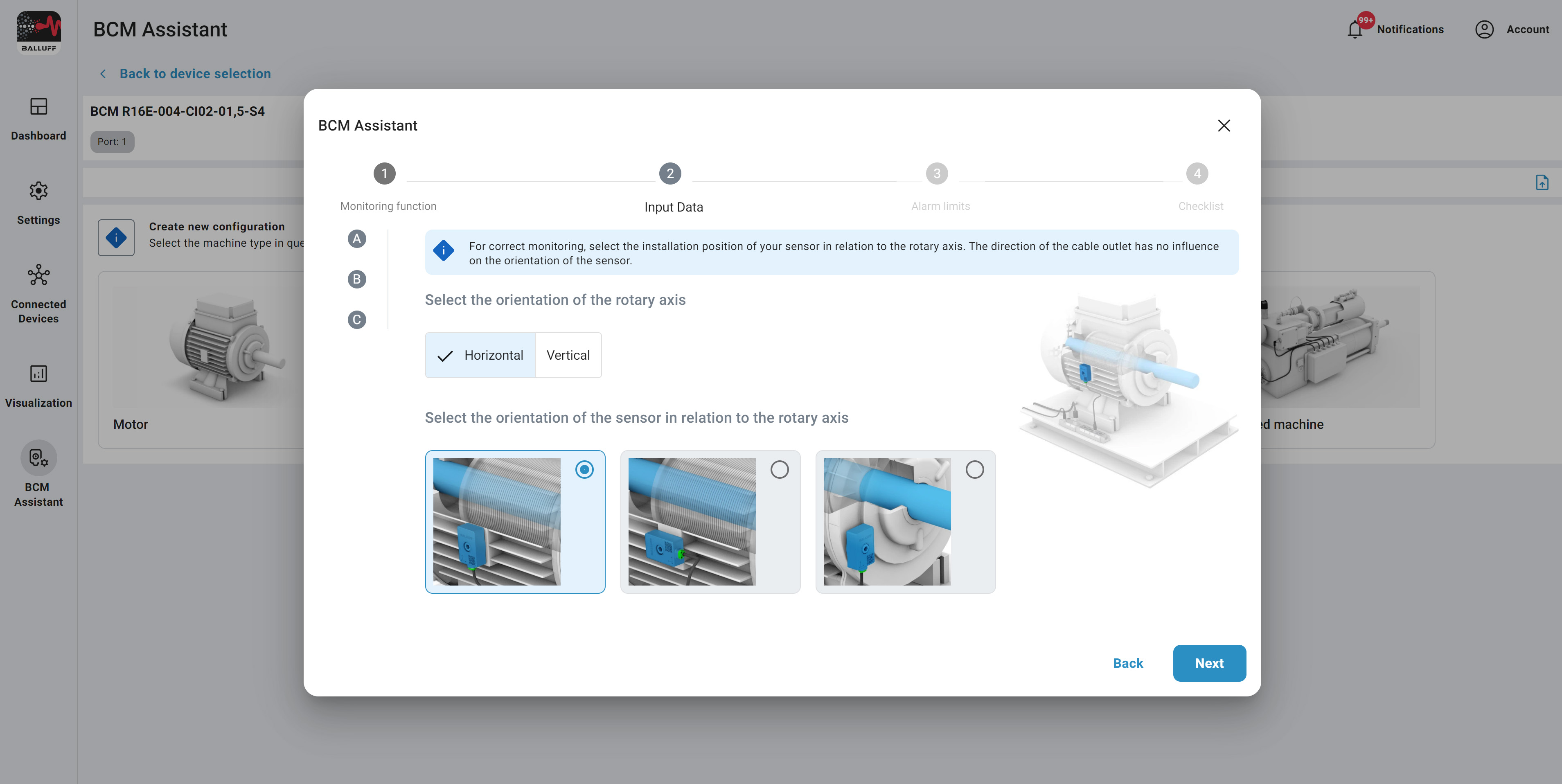

Provide the necessary information (e.g. performance class) used in the application.

Select the orientation in which the sensor is to be mounted on the machine.

Select the orientation in which the sensor is to be mounted on the machine.

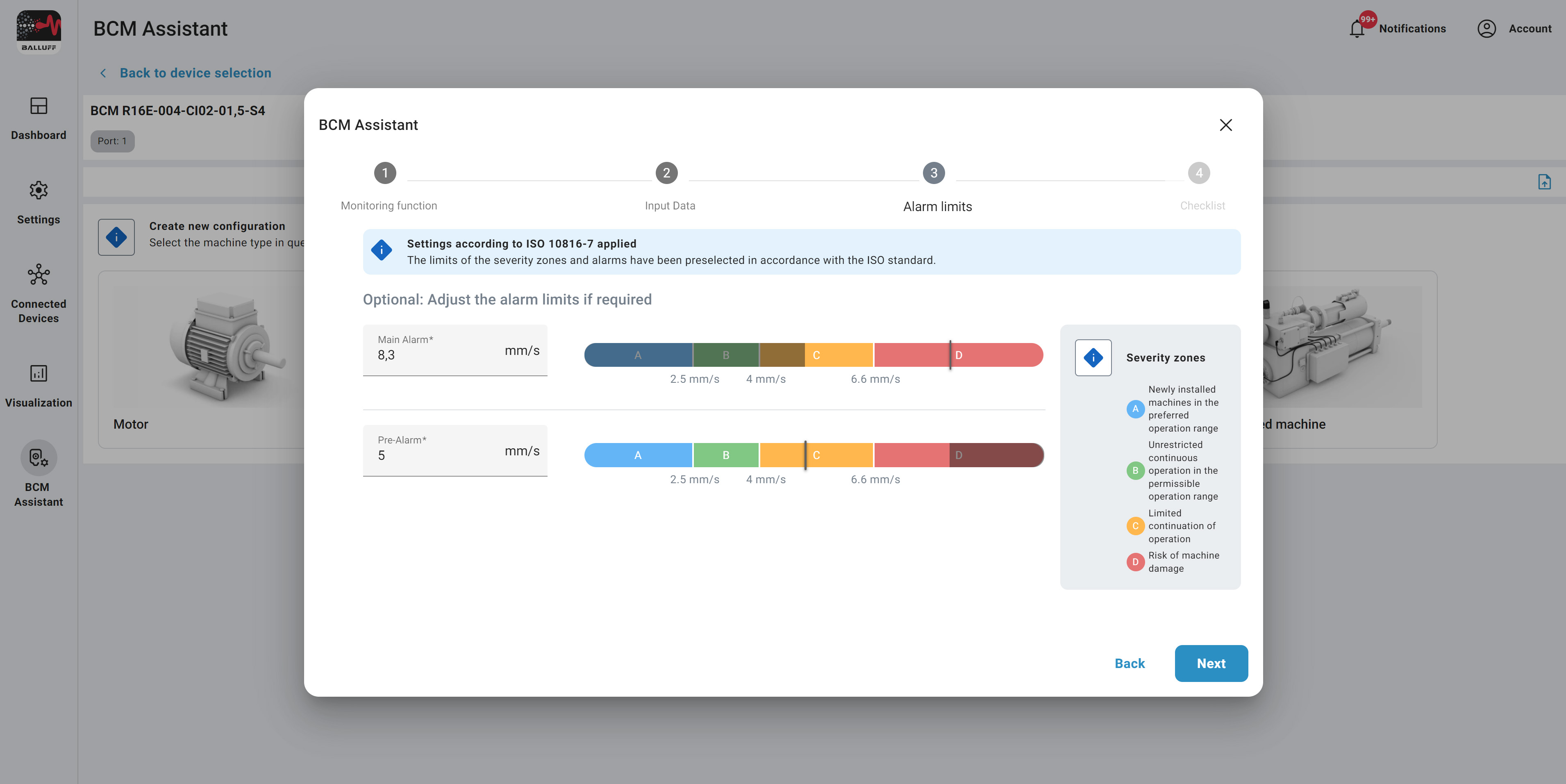

You will receive an overview of the automatically-set ISO severity zones and alarms.

You will receive an overview of the automatically-set ISO severity zones and alarms.

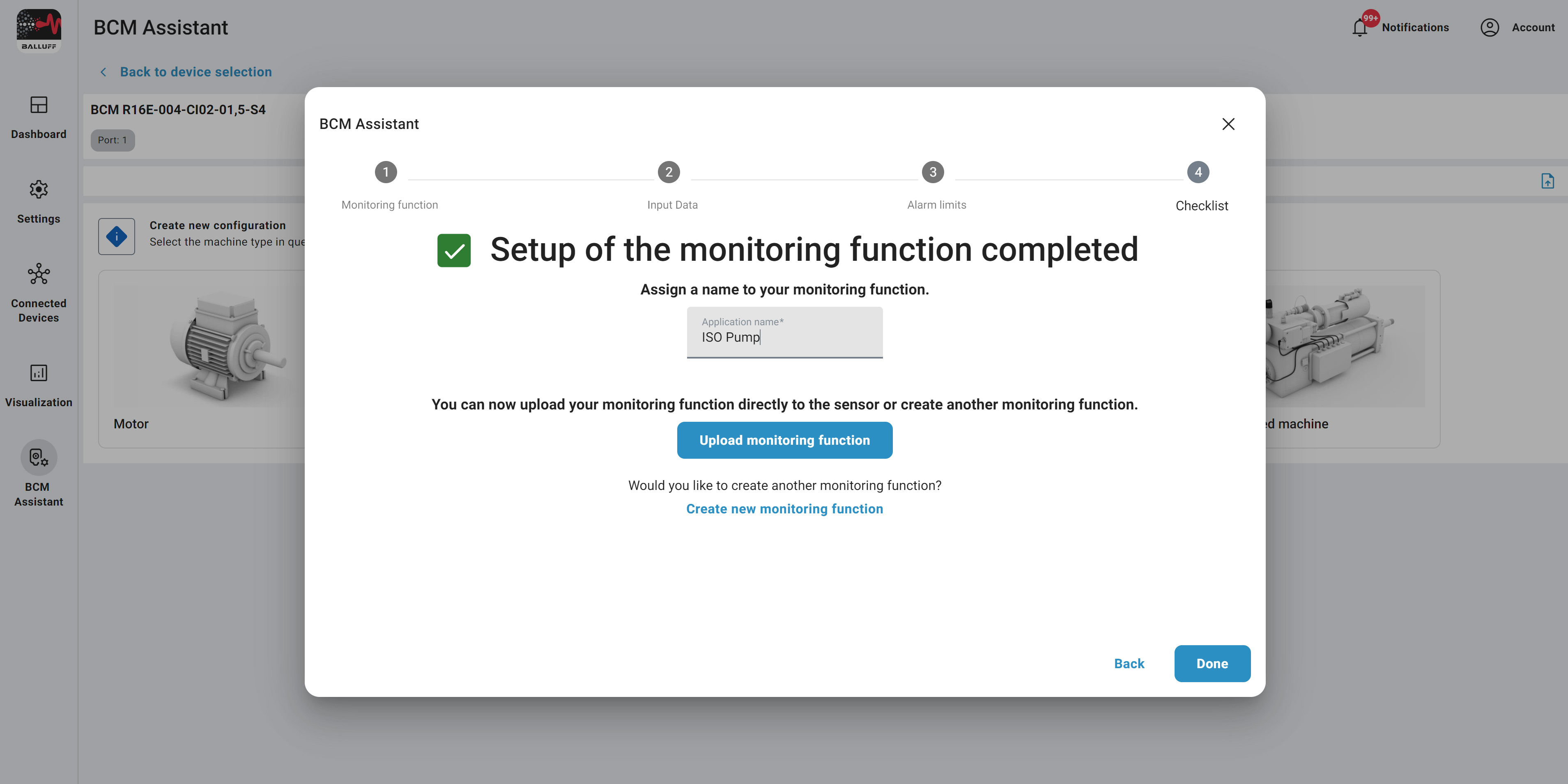

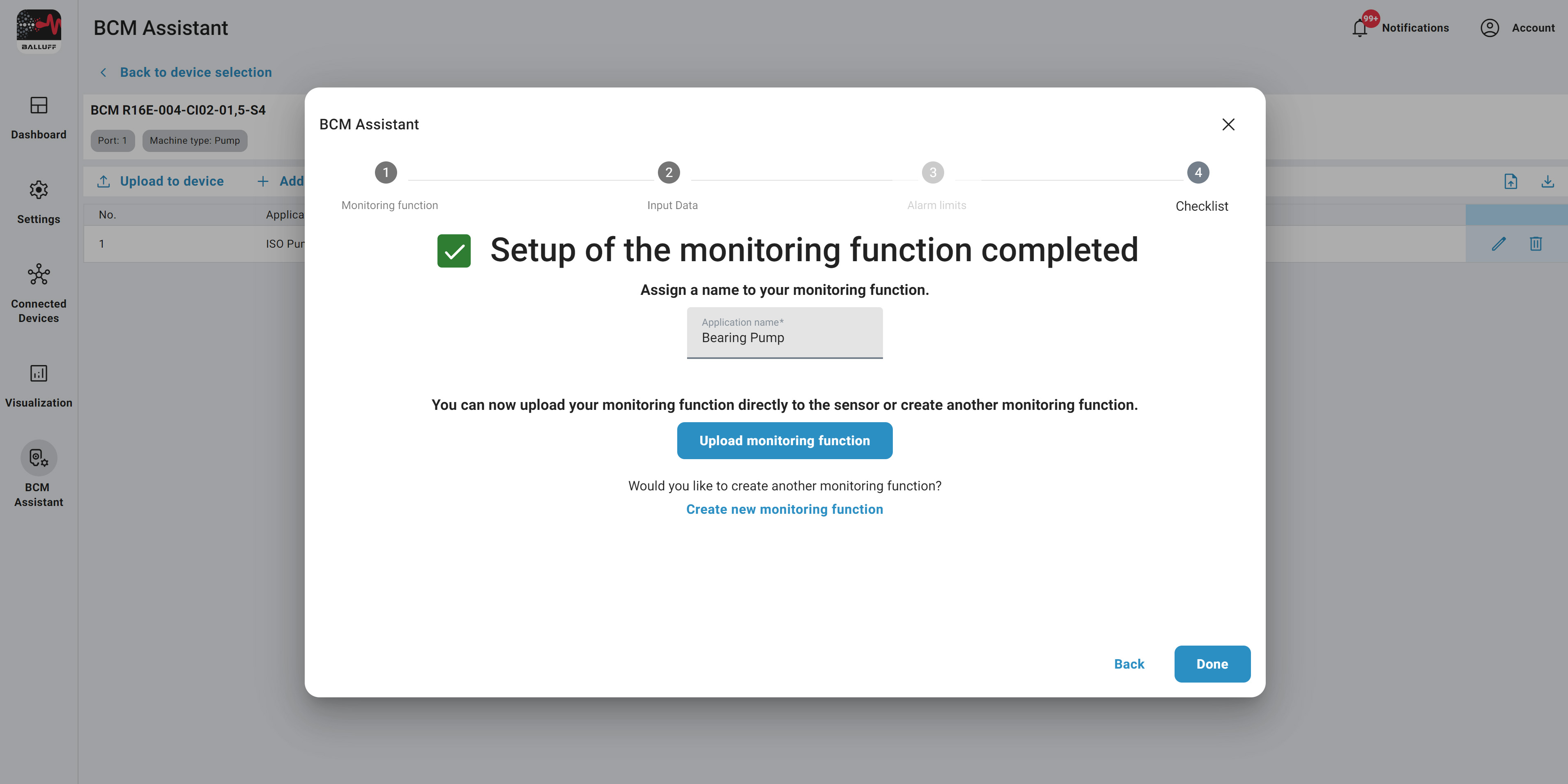

The configuration of your monitoring function is complete and ready for transfer to the sensor.

The configuration of your monitoring function is complete and ready for transfer to the sensor.

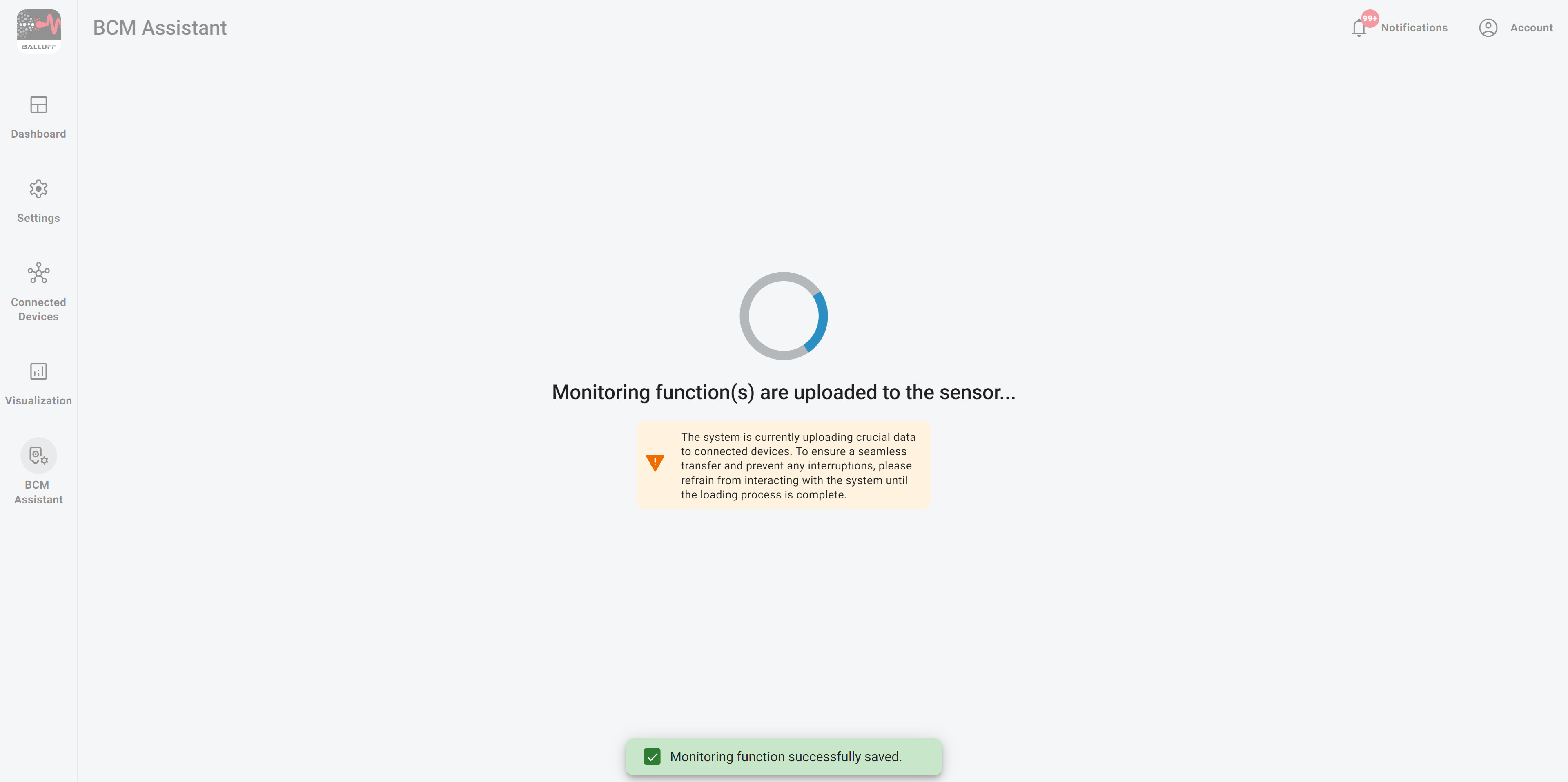

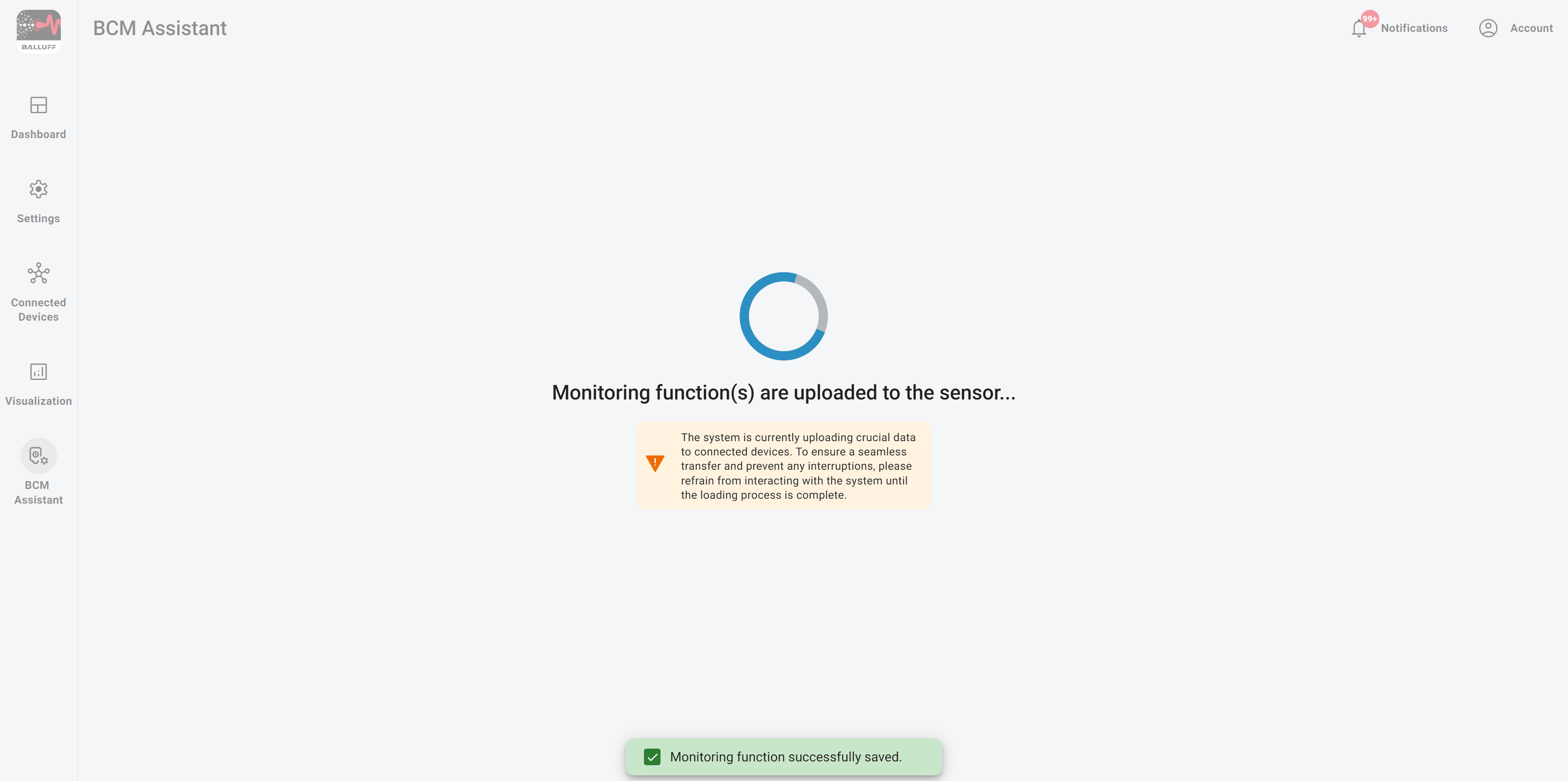

The software wizard sets the relevant parameters and sends them to your sensor.

The software wizard sets the relevant parameters and sends them to your sensor.

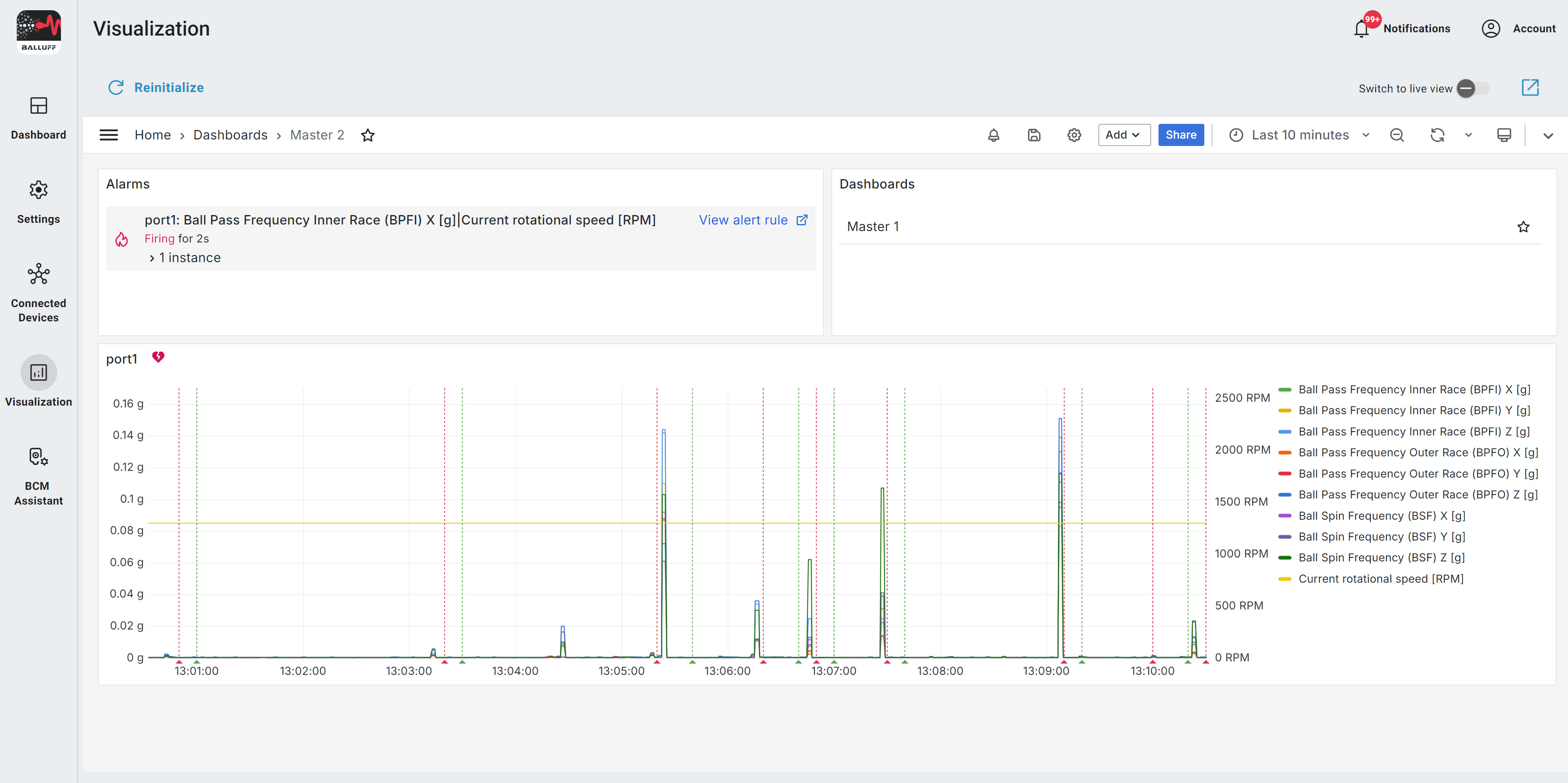

The data relevant to your monitoring function is then displayed in the visualization.

The data relevant to your monitoring function is then displayed in the visualization.

Monitoring bearings

Select the bearing you want to monitor and the wizard will guide you through the rest.

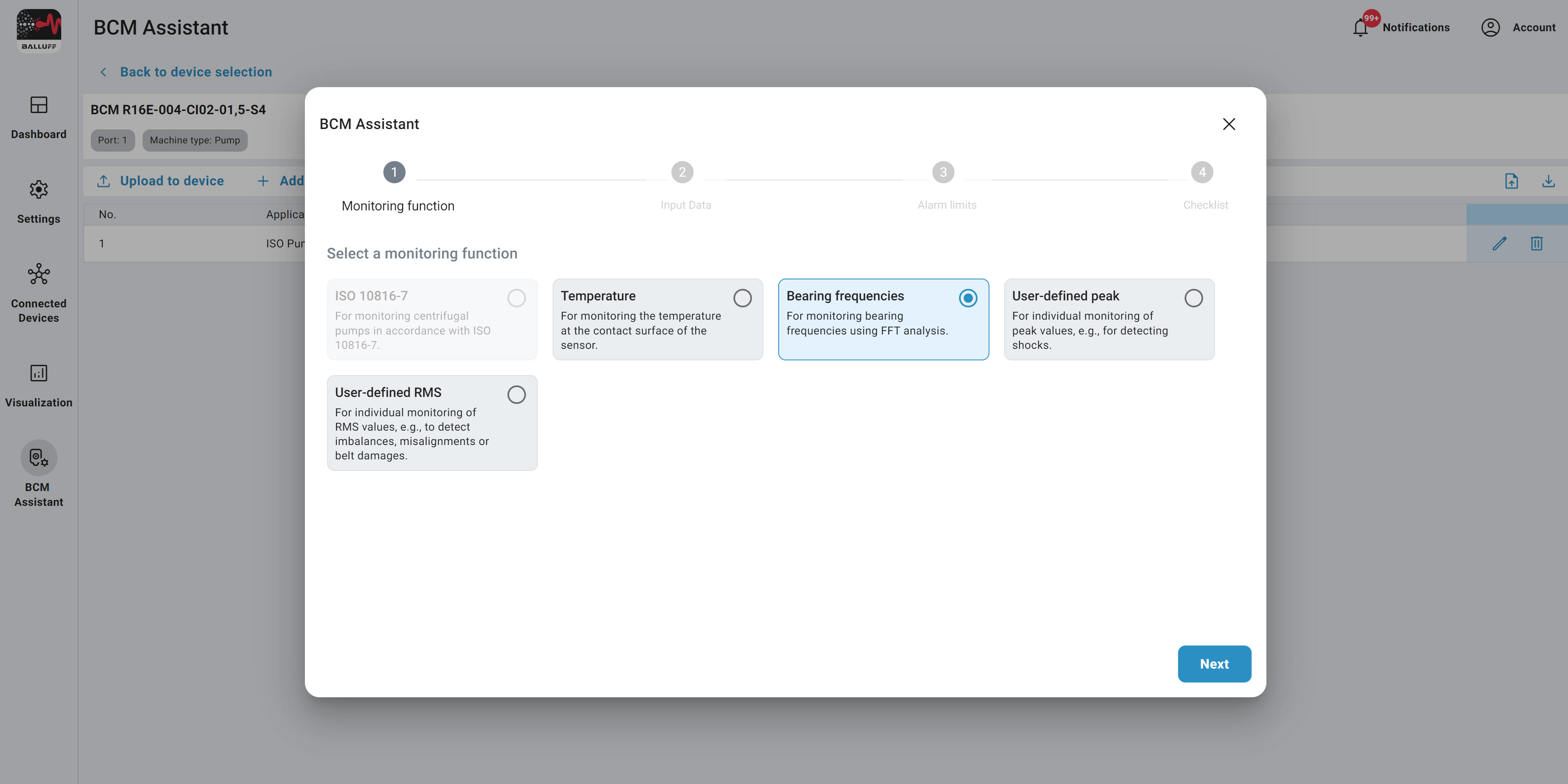

Select another monitoring function (e.g. bearing frequencies) that the sensor should perform.

Select another monitoring function (e.g. bearing frequencies) that the sensor should perform.

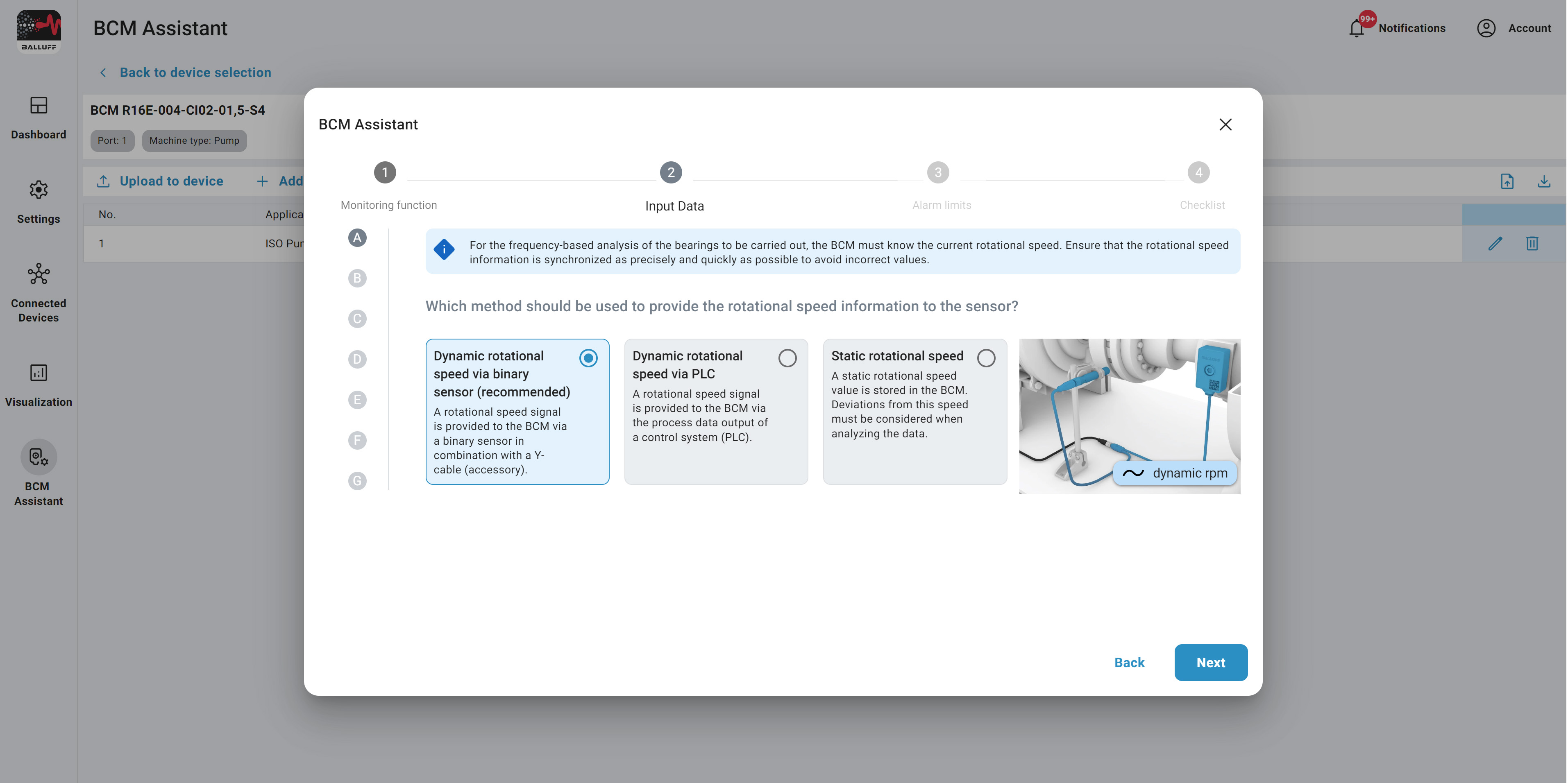

Define the method to be used to provide the speed information to the sensor.

Define the method to be used to provide the speed information to the sensor.

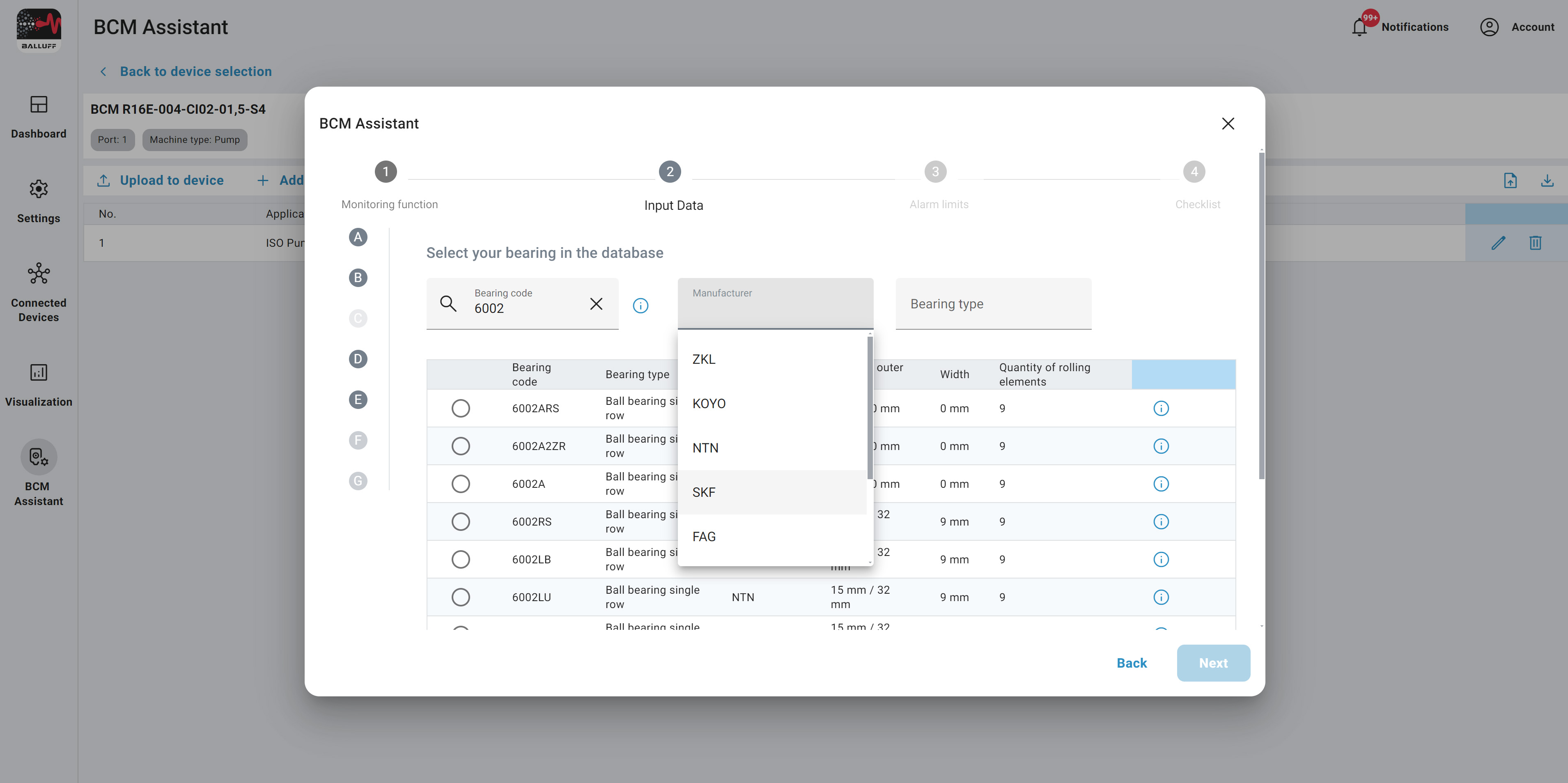

Select a bearing from our extensive database. With more than 160,000 types, you are sure to find the right one.

Select a bearing from our extensive database. With more than 160,000 types, you are sure to find the right one.

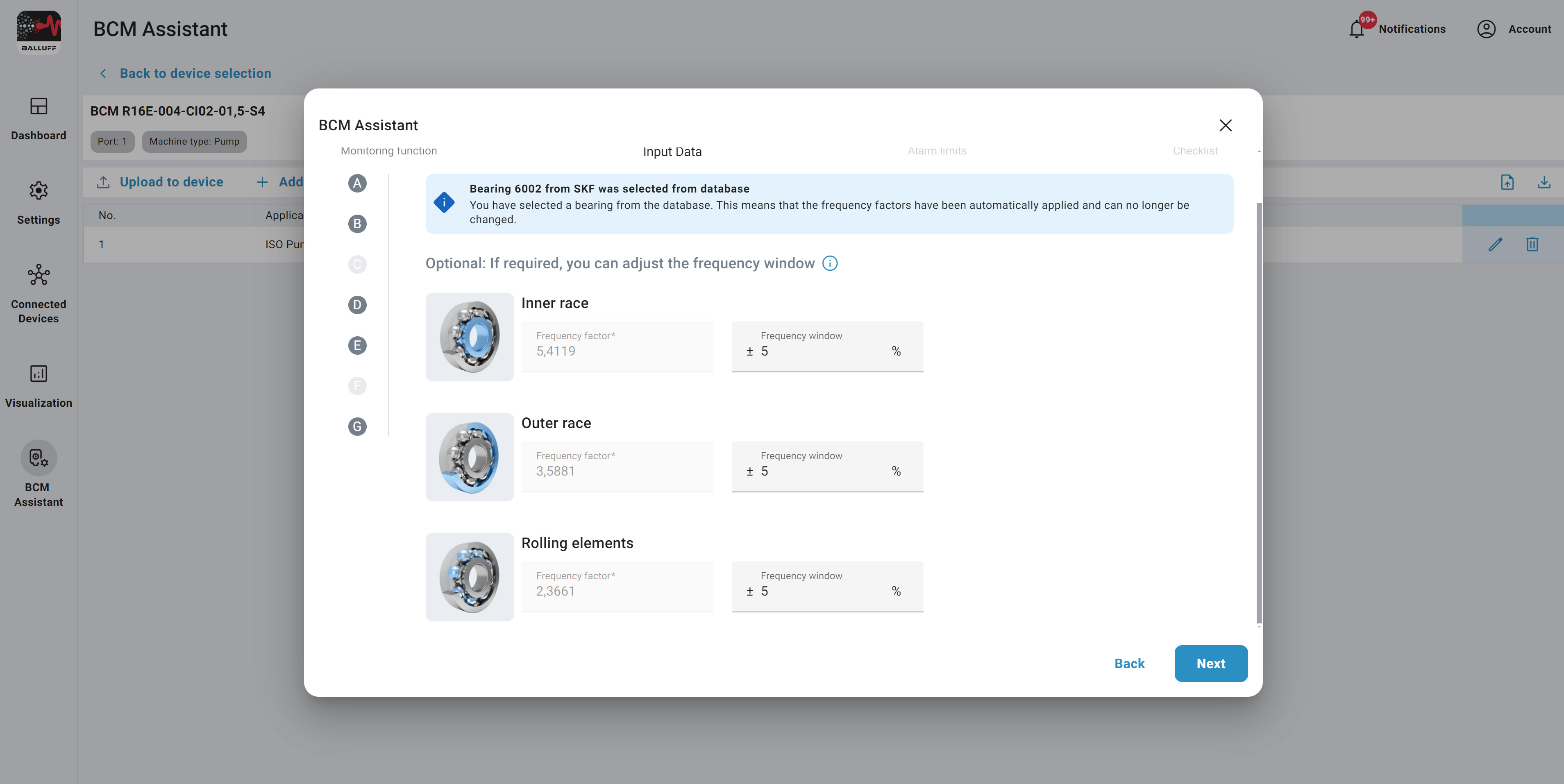

You will receive an overview of the automatically set bearing frequencies (BPFI, BPFO, BSF).

You will receive an overview of the automatically set bearing frequencies (BPFI, BPFO, BSF).

The configuration of your monitoring function is complete and ready for transfer to the sensor.

The configuration of your monitoring function is complete and ready for transfer to the sensor.

The wizard sets the relevant parameters and transfers them to your sensor.

The wizard sets the relevant parameters and transfers them to your sensor.

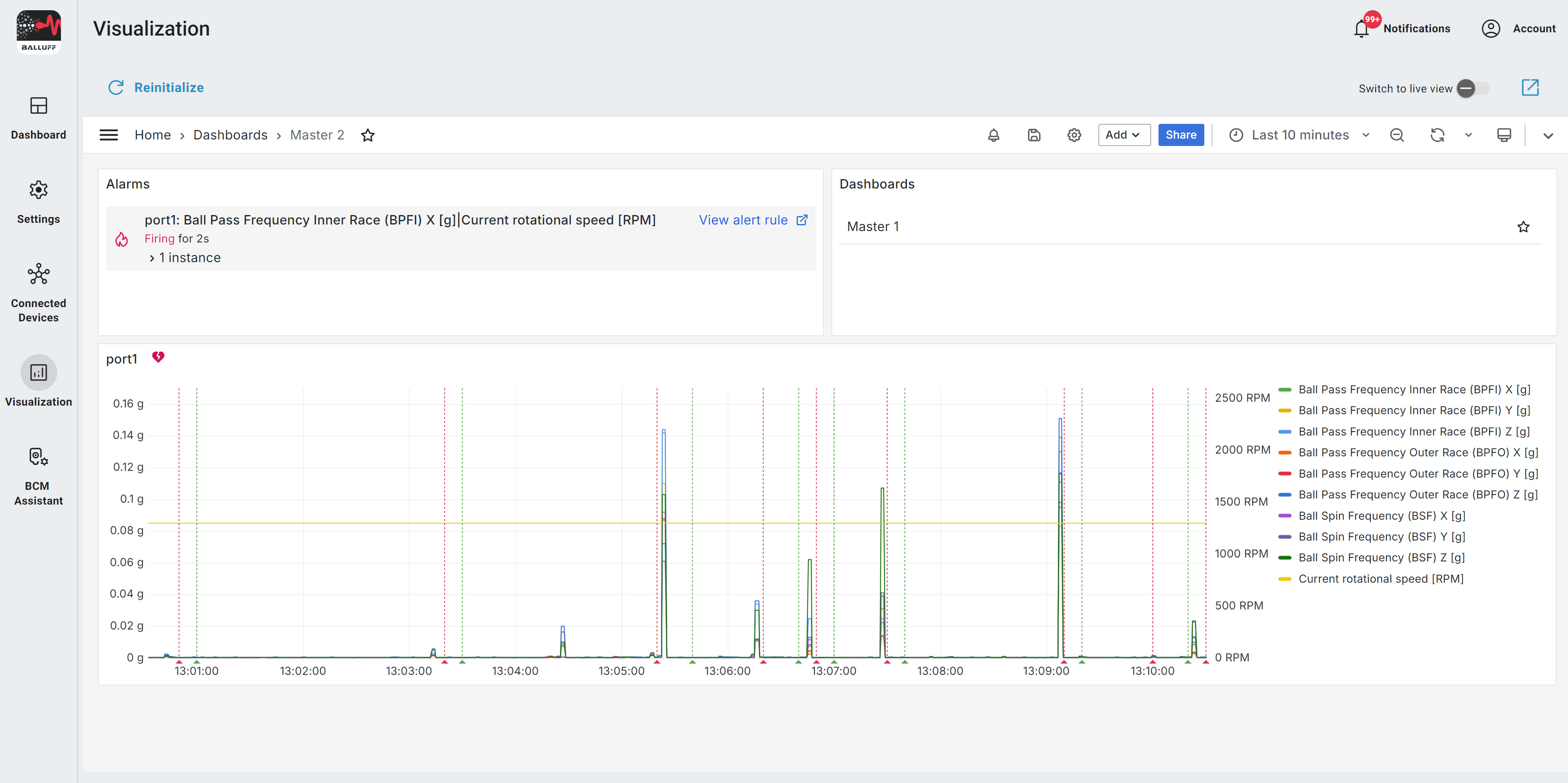

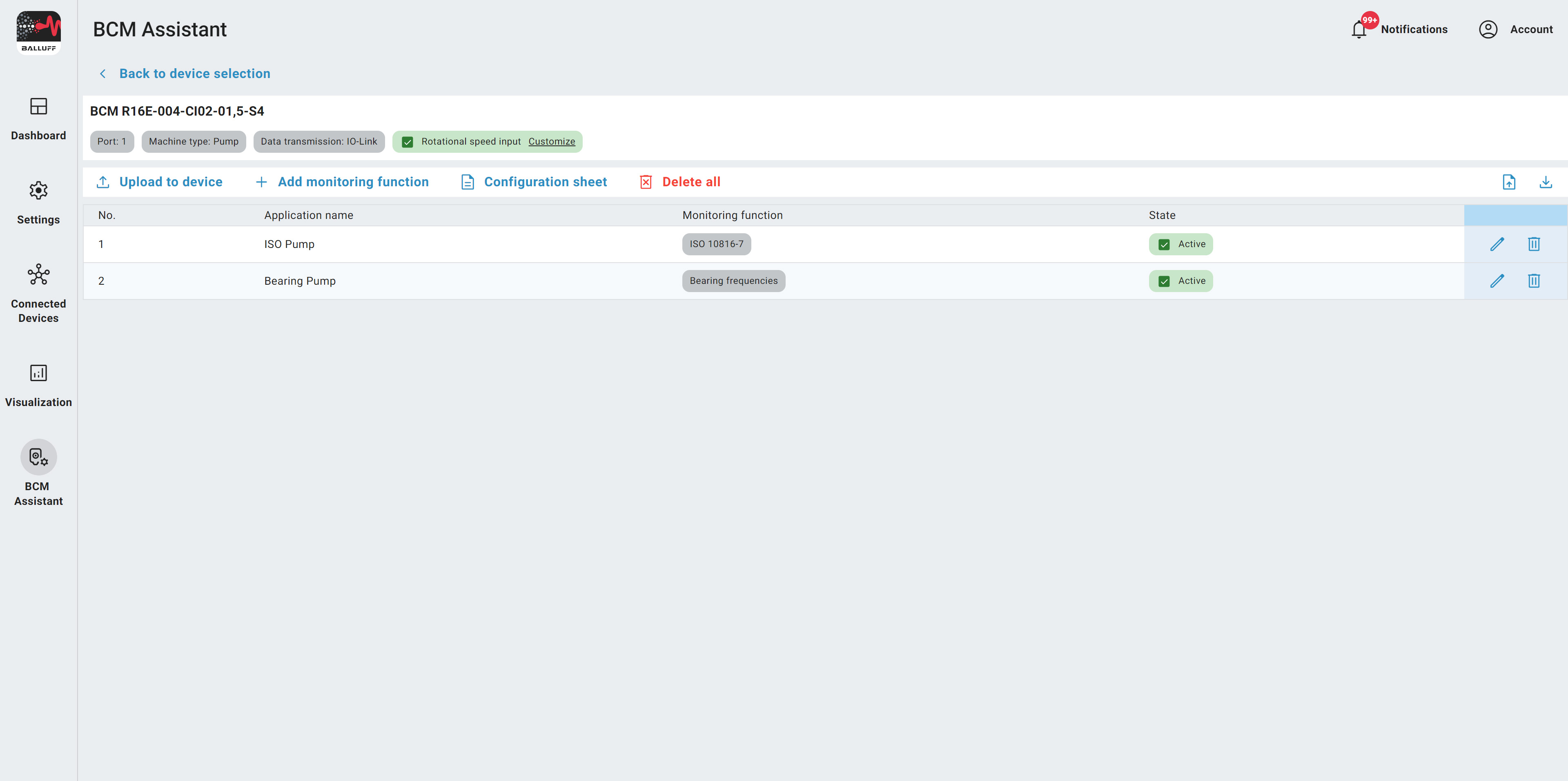

The overview shows that both monitoring functions are active at the same time.

The overview shows that both monitoring functions are active at the same time.

The data relevant to your monitoring function is then displayed in the visualization.

The data relevant to your monitoring function is then displayed in the visualization.